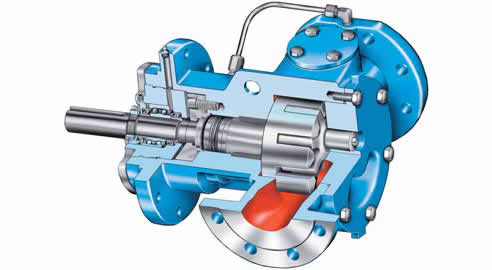

NEWS ARTICLE ARCHIVESViking pumps from Kelair Pumps Australia on light oil duty One of Kelair's customers uses a Viking pump on a light oil duty. The significant difference with this duty compared to many others is the very high suction pressure, typically around 20 Bar. The Viking 4076 series is an internal gear pump, and is well suited to pumping viscous products. Ductile Iron is the standard pump casing material. This range has a differential pressure capability of 17 Bar, as listed on the documentation. The particular customer has a differential pressure of typically around 5 Bar, so meeting that requirement was easy. When the customer advised the suction pressure was to be over 20 Bar, we had to consult the Viking factory. Viking advised; The balanced mechanical seal is required for high suction pressures over 15 Bar (and also for all petroleum industry centrifugal pump standards). The type of seal reduces the otherwise high seal face pressure, thereby extending the life of the mechanical seal. These Viking pumps are flanged (at the pump shaft) for closecoupling. A bell housing or flange adapter is available from the Viking factory to couple the pump directly to the motor. A foot support is optional, in case the preference is for longcoupling (with non-spacer coupling and coupling guard, mounted on a base plate). In this instance, the pumps are to be skid-mounted, so closecoupling is ideal. The advantage of close-coupling is that it holds the pump/motor alignment without the need to re-align after "jolting" when the pump skid has been moved. The 4076 series of Viking pumps are termed "motor speed" pumps. That means they have the capability of being closecoupled if required, directly to 8-Pole (720rpm), 6-Pole (950rpm), and 4-Pole (1450rpm) motors. As the fluids being pumped by gear pumps are often viscous liquids, the pump suction and discharge ports need to be quite large and well designed to minimise NPSH requirements. (Otherwise, in an effort to reduce NPSH requirements, many other gear pumps would generally operate more slowly at 500 rpm or less on the more viscous products. That means having to use a bigger, sometimes more expensive pump and gearbox). Viking has done a great job there, as the NPSH requirements even on heavy-grade gear oils (1,000 to 2,000 cSt) is quite low at only a few metres, even at 950rpm. With correctly sized suction lines, these pumps can move even viscous fluids at quite a flowrate. (Bear in mind, there will always be a requirement for bigger pumps running at even slower speeds, from 50rpm to 350rpm to get NPSH as low as possible on viscous liquids, as pump suction conditions are not always ideal). Internal pressure relief valves are standard on Viking pumps to help protect the entire pumping system from overpressure. All positive displacement (PD) pump types should have some sort of pressure relief built into the discharge line in case of blockage. All PD pumps will continue to pump, even if pumping accidentally against a closed head. That means huge pressure spikes until some form of pressure relief. And Viking has that safety feature built in. Kelair's customer has been using this Viking pump range on light oils, at high suction pressures, for many years now with much success. View Newsletter; |

|

|