Reducing Door Frame Corrosion from Taylors Doors & Frames From the moment a welded door has been installed in your building, severe weather conditions and ambient moist humid coastal conditions can corrode frames. Just prior to installation a typical welded door frame should be re-coated but this adds cost to the initial purchase price. It is also the case that once the frame is installed the exposed surfaces can be re-painted many times over but this does not address the manifold corrosion issues behind the frame in the areas and frame sections where humidity penetrates and that are most difficult to inspect.

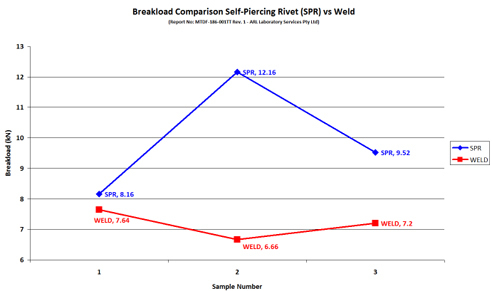

A Taylors door frame addresses the corrosion challenge; On a weld for rivet comparison, independent break load tests show SPR creates a stronger join than welding. Leading automotive and aircraft manufacturers have used this joining technology for years so if it is good enough for BMW, Audi and Jaguar why not your next metal door frame!

|

Taylors Doors and Frames Profile 02 9905 1222 20 Orchard Road, Brookvale, NSW, 2100

|

Stainless Steel and Zinc Plated Hinges

Stainless Steel and Zinc Plated Hinges Stainless Steel Clad Fire Doors by

Stainless Steel Clad Fire Doors by Pressed Metal Door Frames Sydney by

Pressed Metal Door Frames Sydney by Door Frame & Door Kits from Taylors

Door Frame & Door Kits from Taylors Fire Resistant Commercial Doors from

Fire Resistant Commercial Doors from Pressed Metal Door Frames Sydney from

Pressed Metal Door Frames Sydney from Purchasing Door Frames | Taylors Doors

Purchasing Door Frames | Taylors Doors Pressed Metal Door Frames | Taylors

Pressed Metal Door Frames | Taylors Controlling Door Frame Corrosion |

Controlling Door Frame Corrosion | Fire Door Reinforcing Plates | Taylors

Fire Door Reinforcing Plates | Taylors Weld Free Door Frame | Taylors Doors and

Weld Free Door Frame | Taylors Doors and Frame Fixing for Masonry Walls | Taylors

Frame Fixing for Masonry Walls | Taylors Slider Frames for Stud Walls | Taylors

Slider Frames for Stud Walls | Taylors Fire Rated Frame Fixings, Taylors Doors

Fire Rated Frame Fixings, Taylors Doors Fire Rated Doors, Taylors Doors &

Fire Rated Doors, Taylors Doors & Door Frame Fixings, Taylors Doors &

Door Frame Fixings, Taylors Doors & Masonry Frame Fixing, Taylors Doors

Masonry Frame Fixing, Taylors Doors Dry Wall Frame Fixing, Taylors Doors

Dry Wall Frame Fixing, Taylors Doors Metal Door Joining System, Taylors Doors

Metal Door Joining System, Taylors Doors Architectural Metal Door Frames, Taylors

Architectural Metal Door Frames, Taylors