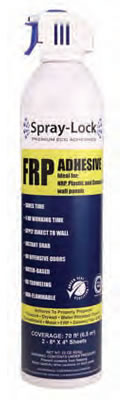

FRP Spray Adhesive Spray-Lock from Allplastics Spray-Lock® FRP Spray Adhesive PRODUCT CHARACTERISTICS Spray-Lock® FRP Spray Adhesive bonds approved wall material for commercial and residential applications. Material must be structurally sound for use in commercial or residential applications. Spray-Lock® FRP uses 60% less adhesive than traditional trowel-on adhesives. Spray-Lock® FRP increases productivity with a faster application rate, saving you time and money. Spray-Lock® FRP comes in easy to use aerosol cans.

SUITABLE SUBSTRATES Spray-Lock® FRP Adhesive adheres approved wall coverings and materials onto the following properly prepared smooth substrates: - Plasterboard, cement sheet, Scyon sheet, timber, MDF, ceramic tiles, metal, FRP (Fibre Reinforced Plastic), concrete, glass, etc. SUITABLE MATERIALS FOR APPLICATION - Acrylic sheet & mirror, polycarbonate sheet & mirror, PETG, MDF, timber, metal, Alucobond, rigid or foam styrene, rigid or foam PVC, Rowlux illusion film, Korogard high impact wall protection, etc. *As substrates and materials vary greatly, compatibility and suitability of substrate and material to be confirmed by customer prior to any production NOTE: Joint compound may need to be primed if it continues to dust. TECHNICAL CHARACTERISTICS Spray-Lock® FRP's formula is a water based acrylic blend spray adhesive that has milky white frost bubbles in appearance and provides immediate shear strength during installation. Spray-Lock® FRP adhesive is solvent free, emits no harmful fumes and contains <0.0g/ml VOC (Volatile Organic Compounds) content. According to EPA Method 8260B. Spray-Lock® FRP uses a safe non ozone depleting HFC propellent. *Green Seal Certified: This product meets the Green Seal™ Standard for Adhesives for Commercial Use, GS-36, based on its reduced hazard to humans, reduced volatile organic compounds, and reduced hazardous ingredients. **According to EPA document: "National Volatile Organic Compound Emission Standards For Consumer Products" for aerosol adhesives. TECHNICAL DATA Chemical Type: Water-based Acrylic Blend Appearance: Milky white frost bubbles Odour: Sweet mild odour Flash point: Will not burn NFPA 704 Flammability Rating: 0 (Non Flammable) Storage: Do not subject to freezing temperatures. Shelf life: 3 years if unopened Open time: 4 hours Dry time: Once adhesive is dry to touch (10-20 minutes) VOC content: <0.0g/ml per EPA Method 8260B STANDARD AEROSOL Shake aerosol can well. Snap blue tab on top of trigger to activate the can, aim at desired substrate. Pull blue lever to spray adhesive. COVERAGE GUIDE - STANDARD AEROSOL 70 ft2 (6.5 m2) 2 - 8ft X 4ft Sheets Coverage rates are a guide and figures will increase or decrease depending on the spraying technique implemented Please refer to Installation Guidelines for detailed instructions.

|

Allplastics Engineering Pty Ltd Profile 02 8038 2000 Unit 20, 380 Eastern Valley Way, Chatswood, NSW, 2067

|

ADVANTAGES

ADVANTAGES

Stone Look Cladding Panel by Allplastics

Stone Look Cladding Panel by Allplastics Radiant Effect Acrylic Glass by

Radiant Effect Acrylic Glass by Anti Slip and Translucent Optic Flooring

Anti Slip and Translucent Optic Flooring Custom Fluorescent Shop Window Displays

Custom Fluorescent Shop Window Displays Handrails for Hospitals from Allplastics

Handrails for Hospitals from Allplastics Viewing Panels for Aquariums by

Viewing Panels for Aquariums by Abrasion Resistant Polycarbonate Sheets

Abrasion Resistant Polycarbonate Sheets Acrylic Brochure Holders by Allplastics

Acrylic Brochure Holders by Allplastics Acrylic Panels for Transparent Swimming

Acrylic Panels for Transparent Swimming Magnetic High Pressure Laminates for

Magnetic High Pressure Laminates for Textured Acrylic with Patterns from

Textured Acrylic with Patterns from Shatter Resistant Coloured Acrylic

Shatter Resistant Coloured Acrylic Plexiglas LED for Lighting Surface by

Plexiglas LED for Lighting Surface by Cast Acrylic Block Panels for Swimming

Cast Acrylic Block Panels for Swimming Safety Barriers and Pool Compliant

Safety Barriers and Pool Compliant Fluorescent Window Displays from

Fluorescent Window Displays from Quality Pool Windows and Portholes from

Quality Pool Windows and Portholes from Chemical Resistant Rigid PVC Sheets from

Chemical Resistant Rigid PVC Sheets from Acrylic Mirror Architectural Display by

Acrylic Mirror Architectural Display by Translucent Polycarbonate Loft Flooring

Translucent Polycarbonate Loft Flooring