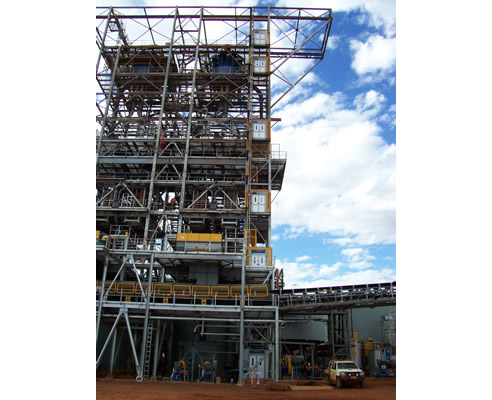

NEWS ARTICLE ARCHIVESIndustrial Lifts at Christmas Creek Mine from Alimak Hek

Christmas Creek Mine sees Australia's first Alimak Crushing Services International specifies three Alimak SE 1200 kg industrial lifts for inclusion on the Christmas Creek Mine expansion. Installed in the mine's iron ore processing facilities, these are the first permanent Alimak lifts in Australia installed on an iron ore crushing plant. Fortescue Metal's Christmas Creek mining operations has undergone a two phase expansion program to increase the capacity of the mine's iron ore operations. Located in the east Pilbara region of Western Australia, the Christmas Creek mine expansion included the construction of two ore processing facilities and a crushing hub; the first in Australia to be fitted with Alimak industrial men and materials lifts. Completed in December 2012, the expansion has increased production to more than 50 million tonnes of ore per annum. As the prime contractor for the expansion's construction works, Crushing Services International specified the inclusion of the lifts in the ore processing facilities in order to maximize plant reliability. Minimizing production downtime at the processing facilities was a critical factor, as the iron ore requires crushing, screening and processing prior to sale and transport. Used for the transportation of materials, equipment and the operations and maintenance personnel on site daily, the three Alimak SE 1200kg industrial lift improve efficiency of operations at a key stage of the mine's processing circuit. Phase one of the expansion involved the construction of a 20mtpa ore processing plant, used to crush, screen, scrub and de-sand the wet table ore. The first Alimak industrial lift was installed in the de-sands building of the processing plant in March 2011, and required careful engineering to fit the lift system inside an existing portion of the building's structure. In order to take full advantage of the limited space available, an Alimak FE mast was selected for its narrower depth and smaller dimensions, in place of the standard Alimak 650 mast. Phase two of the expansion included the construction of a second ore processing plant and a remote crushing hub. The second Alimak 1200kg industrial lift was installed in the facility's tertiary crusher in May 2012, while February 2013 saw the final Alimak lift installed in Plant 2's de-sands building. The Alimak SE 1200kg personnel and materials lift was selected for all three buildings due to its flexible size. With a car size of 1.3 m x 2.1 m, the Alimak SE 1200 is suited to carry palletized loads and improves safety and emergency procedures on site by accommodating the dimensions of an emergency stretcher.

|

|

|