NEWS ARTICLE ARCHIVESThermal Imaging and Mechanical Engineering from FLIR Systems

Thermal imaging helps build high-performance electrical racing car Every year, engineering students from around the world are challenged to design and build a single-seat racing car in order to demonstrate their knowledge and talent. In a worldwide competition, called Formula Student, this racing car is then put to the test in static and dynamic events, which test the performance of the vehicle. The Technical University of Delft in the Netherlands has been participating in the Formula Student competition since 2001. Again in 2014, Delft's DUT Racing team is aiming at designing the most efficient and high-performance electrical racing car, this time with the help of thermal imaging cameras. Formula Student aims to inspire and develop enterprising and innovative young engineers. This high-performance engineering project is not only extremely valued by colleges and universities worldwide, it is also viewed by the motorsport industry as the benchmark for engineering graduates, transitioning them from university to the workplace. Formula Student started back in 1981 in the US, today the competition is joined by over 500 teams. The DUT Racing team now consists of 80 people. Students of the DUT Racing team are housed at the impressive D:DREAM hall at the Delft University campus where they can make use of the most advanced technologies to design their racing car. One of these technologies is thermal imaging. When designing an electrical car, it can be important to monitor temperatures in real time. In the case of DUT Racing team, a thermal imaging camera from FLIR Systems is used to check for hot spots in battery cells, monitor the temperature profile of car tyres and test car electronics.

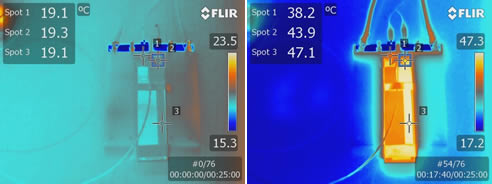

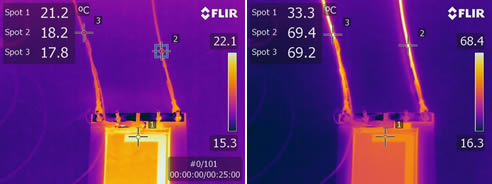

Lightweight components The attention to weight applies to almost every car component. "In the case of car batteries, the more energy - Joules - you require, the more weight you will need," says Bauke Kooger, Chief Accumulator at the DUT Racing team. "We use a FLIR T640 thermal imaging camera to monitor the temperature and detect hot spots of battery cells with different load cases. To this end, we simulate cycles that are typical of an endurance race, which is part of the competition's dynamic tests. This way, we want to be able to see where we need to place the temperature sensors and how we need to size the cooling system. Also, the FLIR thermal imaging camera allows us to see hot spots located at bad connections in an assembled accumulator." Even cables are tested. During a current test, the DUT team is checking whether using a cable with a lower cable current rating is detrimental for the performance of the car. If not, it would allow the team to use even lighter cables.

The weight issue also applies to the car tyres, as wider tyres will provide more grip, but will also be heavier. "We design the tyres ourselves," says Marinus Geuze, Chief Electronics at the Delft Formula Student team. "With the FLIR thermal imaging camera, we can monitor the temperature profile of the tyre. A uniform temperature across the full tyre surface is very important in terms of performance. With the temperature information we receive from the thermal imaging camera, we can adjust the suspension of the car."

Thermal imaging in any design stage

FLIR T640 camera "The important thing for us was obtaining good video images to be able to really monitor the component behaviour during a cycle in real-time," says Bauke Kooger. "We definitely like the resolution and image quality of the FLIR T640. And the camera is so easy to use, that you hardly need any training to get started." |

|

|