Bituminous oils, pitch or waste lubricants provide specific challenges for gear pump operators. Some require heating to high temperatures while others are abrasive to internal components of the pump. However, each of these factors can be effectively managed by correct pump alterations, and in the case of dealing with both high heat as well as an abrasive solution, further adaptations can be made.

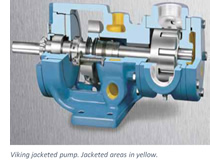

Highly viscous substances such as bitumen and pitch must be heated to a constant, elevated temperature to keep the solution from congealing or hardening within the pump during operation.

According to Mr Alex Calodoukas, Regional Sales Manager at Kelair Pumps, once a customer has chosen their pump, further heat considerations must be made.

"High heat results in expansion of rotating components within the pump, and because of this, clearances must be increased to allow for this expansion.

"Not only do the rotating components expand, they expand at different rates depending on their shape, size and material. At Kelair, we are aware of these factors and increase clearances to ensure that there is no contact between the moving and stationary components.

"We know how important it is to get the pump and pipework right from the beginning (in particular jacketed pipework), so we not only guide our customers in selecting suitable sized pumps, we can also help with pipe sizing if required," says Mr Calodoukas.

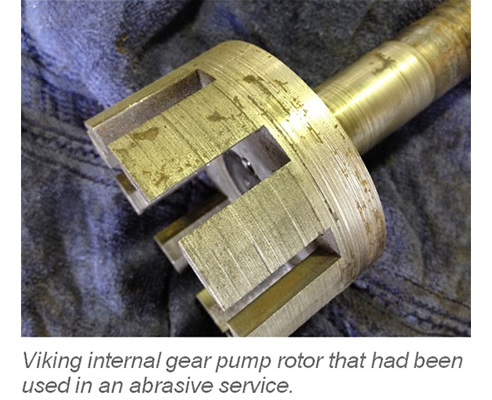

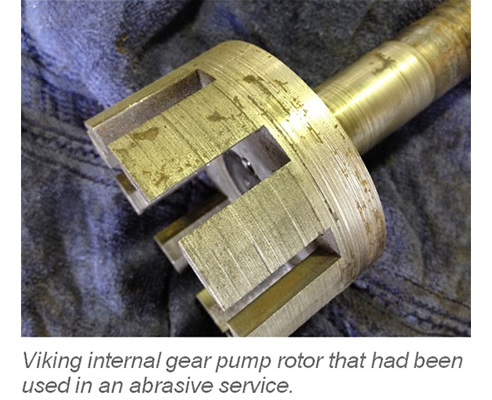

Abrasive solutions

Reducing wear on the pump for harsh applications can be achieved by lowering the pump's RPM, says Mr Calodoukas.

"The wear rate relationship of a pump is exponential to RPM. When pumping abrasive solutions, we can slow down our Viking gear pumps to the desired rotations per minute for minimal wear.

Abrasiveness combined with high heat requirements

When pumping solutions that require both a high heat as well as a lowered RPM, further adaptations must be considered.

"Pumps that can achieve the highest temperatures have soft internal components such as carbon bushes. Carbon however, cannot withstand abrasives, so hard, self-lubricating products like bronze or tungsten carbides must be used.

"The problem with this is that tungsten carbide due to its rate of expansion has temperature limitations. The biggest challenge then lies in finding suitable materials or strategies that cater for both heat and abrasiveness," says Mr Calodoukas.

Kelair recently installed a Viking pump at a refinery which required heating to above 250 degrees Celsius. The fluid also contained abrasives, so a unique solution had to be developed.

"This high heat is challenging for any gear pump, and as the fluid was also abrasive, we had to collaborate closely with the customer to find an effective solution.

"Our unique relationship with Viking also means that we have the option to use their expertise on individual projects. We can discuss with Viking and investigate different materials with expansion rates and toughness that will work for unique applications. This is a major benefit of Kelair's customer service capabilities."

Product availability and service

Viking pumps are a heavy duty brand of gear pumps and due to Viking's extensive research and development programs, they are able to be used for a diverse range of pump applications. Kelair continues to be the only supplier of Viking pumps within Australia.

If you are interested in learning more about the Viking pump range please call Kelair Pumps on 1300 789 466.

This can be achieved by using either a hot oil or steam jacketed pump, which will keep the substance heated to a more fluid consistency at both start-up and throughout operation. The Viking range of gear pumps supplied by Kelair also has an electrically heated pump which can be used when hot oil or steam is not an option.

This can be achieved by using either a hot oil or steam jacketed pump, which will keep the substance heated to a more fluid consistency at both start-up and throughout operation. The Viking range of gear pumps supplied by Kelair also has an electrically heated pump which can be used when hot oil or steam is not an option.