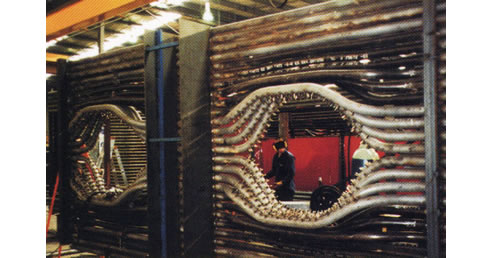

NEWS ARTICLE ARCHIVESPipe Bending Melbourne from U-Neek Bending A vast experience in Australian and international industry with a focus on power and mining give U-Neek Bending a reputation for excellence in design and production of innovative industry solutions. When it comes to precision bending, rolling, welding and component fabrication, U-Neek stands alone in service, quality and professionalism with high regard to cost effective production. U-Neek Bending is an Australian owned company with its head office and main workshop in Dandenong Victoria. We are a leading supplier of components and sub-assemblies to the power generation, Oil & Gas, Chemical and Food Processing industries with proven experience handling various materials including Mild Steel, Chrome-moly, stainless Steel and Titanium. Our capabilities include Tube and Sectional Bending, Rolling, Fabrication and Testing of the final products. We manufacture Power Station Boiler tube systems including Superheaters, Reheaters, Economisers and Headers along with separate Long and Tight Radius bends for maintenance of the boilers systems. Capabilities: Tube and Sectional Bending Rolling, Fabrication and Testing of the final products. Products: We manufacture Power Station Boiler tube systems including Superheaters, Reheaters, Economisers and Headers along with separate Long and Tight Radius bends for maintenance of the boilers systems. Other products include expansion duct profiles, boiler tube shields for internal and external fitment, heat exchangers, heating and cooling coils and swaging of all types and sizes of boiler tubes. Services: Include fabrication and welding as per customer's specifications and regulatory codes such as AS1228, AS4458, AS4041, AS1554, AS3992 and ASME. This service includes carrying out all non-destructive testing requirements, collating of QA documents and preparing MDR's. Our skilled staff work in a modern well equipped factory with CNC Bending and Rolling Machines set-up to bend and curve all types of tubes and components. Our comprehensive fabrication facilities with high capacity overhead cranes and the latest welding machines including orbital welders are able to handle the most complex of shapes and sizes. Emergency Breakdown Service: U-Neek Bending are totally committed to urgent breakdowns where we can supply individual bends and components within a matter of hours from receipt of the information, we strive to provide personalised service to all our customers.

|

|

|