NEWS ARTICLE ARCHIVESHigh Temperature Pumps by OBL from Kelair Pumps Australia

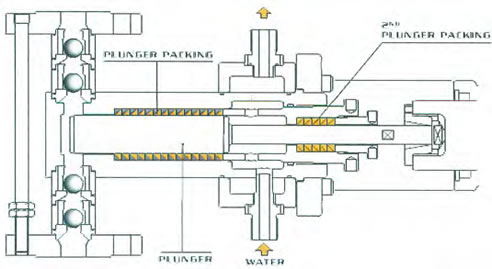

Case Study Difficult application resolved with OBL Kelair's client, an engineering consulting house approached us to select pumps for a nickel process pilot plant. Pilot plants are notoriously difficult to size pumps for since they have all the process challenges of a full scale plant, but on a very small scale. One particularly difficult application was described as the Thermalite feed, pumping molten magnesium oxide (MgO), essentially molten salt. Kelair's engineers looked at several sources for this application. Centrifugal pumps were considered but the actual maximum flow required was only 0.37m3hr, which is too low for any centrifugal pump. Re-circulating part of the flow was considered but this was impractical as up to 90% of flow would have to be recirculated which was unacceptable from a process point of view. The pump would have to deliver molten salt, at up to 0.37m3/hr at 5.8m at 210°C. A specialised high temperature pump was selected from the OBL range. OBL is a European metering pump manufacturer and is part of the IDEX Group, one of the world's largest producers of positive displacement pumps. The TLF-series is a plunger-style pump with two sets of packing. The first plunger packing contains the molten magnesium in the pump head and the second plunger packing seals the gear-box. Water is circulated between the two sets of packing to protect the pump from the high temperature product. There is sufficient area between the pump head and the water cooling area to maintain the product temperature within the pump. The process required a variable flow rate which was achieved by an OBL ZC linear electrical stroke actuator via a 4-20mA signal. The pump motor speed was fixed at 1450rpm. The pump was fitted with a 0.75kW 415V/50Hz IP56 motor and 240V/50Hz supply provided for the stroke actuator. |

|

|