NEWS ARTICLE ARCHIVESIndustrial Lifts for Maintenance Access from Alimak Hek

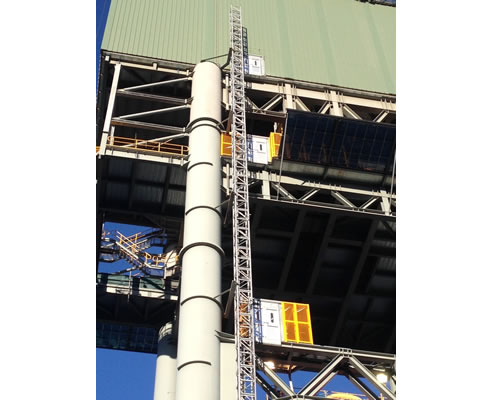

Alimak industrial lift provides An Alimak industrial lift has been installed at Ernest Henry Mining, located in north-west Queensland, providing maintenance workers with access to four levels of the headframe. Used daily, the Alimak lift allows workers to complete operation, servicing and inspections of the hoist winder equipment. Following completion of its open pit operations in 2011, Ernest Henry Mining (EHM) transitioned to underground mining and commenced trucking ore from the mine via a decline. In May 2012, EHM started construction works to sink a new hoisting shaft as part of a $589 million expansion project to enable production at its new underground mine to double, and extend the life of the mine to at least 2024. When commissioned in 2014, the 1000m deep underground shaft will increase production to six million tons per annum, to produce more than 50,000 tons of copper and 70,000 ounces of gold in concentrate. An Alimak industrial lift provides operations and maintenance access to the four levels of the shaft's headframe. Located above the underground mine shaft, the headframe, or winder tower, is a structural frame used to support the winding mechanism of the mine's hoists. Providing access to the underground mining facility, these hoists are vital in the movement of ore out of the mine for processing.

Contained within the 70 metre-high winder tower are the hoists' winding mechanisms, including hoist sheaves, cable drum, winder drive and control and switch rooms. An Alimak industrial lift has been attached to the headframe structure, providing operators and maintenance workers with access to the four levels of the headframe for routine daily equipment operation, servicing and inspections. The incorporation of the Alimak industrial lift as part of the headframe has improved safety of operations on the mine site, providing a means of emergency access and evacuation, should an injury occur on the headframe. With a car size of 1.3 x 2.1 m, the Alimak SE 1200kg lift was selected to meet site safety requirements, with the extended car size able to accommodate the dimensions of a standard stretcher. The Alimak industrial lift can be installed on almost any existing structure, due to its flexible and modular design. It is a very cost effective solution, as the lift does not require a lift shaft or motor room like traditional traction elevators. |

|

|