NEWS ARTICLE ARCHIVES

Kelair-Bilvet Nutrient Removal Units from Kelair Pumps Australia

Product Enhancement

Kelair-Blivet biological

Nutrient Removal

plant

In recent years the harmful effects of eutrophication due to excessive nitrogen and phosphorus concentrations in the aquatic environment in many parts of

the world have been well documented. Discharges from wastewater treatment plants have, in many cases, been significant contributors to this problem.

In addition to stimulating eutrophication, nitrogen in the form of ammonia can exert a direct demand on dissolved oxygen (DO) in a waterway and can be toxic to aquatic life.

A negative impact on waterways may still remain even when a treatment plant converts ammonia to nitrate by a biological nitrification process, as the

resultant nitrate can stimulate algae and phytoplankton growth. Phosphorus also contributes to the

growth of algae.

Due to these documented problems, many regulatory authorities around the world have responded with more stringent discharge standards for sewage and effluent treatment plants.

The engineers behind the design of the Kelair-Blivet™ have now responded to this requirement by redesigning the Blivet to include the option of biological nitrification and denitrification while still maintaining the advantages of the

"all-in-one-package sewage-treatment plant design".

Phosphorus removal can also be partly catered for by biological removal and the addition of chemical dosing for more stringent discharge requirements.

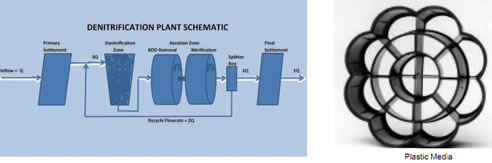

Process Outline

The new treatment plant

layout is based on the well

established Modified

Ludzck Ettinger (MLE) process. The process includes

the addition of an anoxic

zone, followed by an aerobic zone. Additional rotor

length is incorporated within the treatment plant to

provide for the conversion

of ammonia to nitrate

(nitrification) and an internal recycle within the treat-

ment plant back to the anoxic zone to provide for the

conversion of nitrate to

nitrogen gas (denitrification). The removal

of BOD is catered for within

the aeration zone.

Process Description

The new treatment plant layout has six sections all of which are accommodated within one to two Fibre Reinforced Plastic (FRP) tanks depending on the

effluent loadings.

The treatment plants are divided into the following zones:

- Primary Settlement

- Denitrification Zone:

- Anoxic Zone

- Aeration Zone:

- BOD Removal Zone

- Nitrification Zone

- Splitter Box

- Final Settlement

- Sludge Storage

Primary Settlement

Each Kelair-Blivet™ NR Unit is capable of receiving raw sewage and settling the gross solids without recourse to mechanical means. It incorporates lamella or parallel plates to enhance efficiency and utilisation of space. The Primary Settlement zone reduces the Suspended Solids by 75% and the BOD

by 25% to 30%. This zone is relatively maintenance-free and contains no moving mechanical or electrical devices. Lockable FRP covers with easy man access and sufficient ventilation are provided.

Denitrification Zone

Effluent from the Primary Settlement zone is mixed with recycled flow from the end of the Aeration zone. These two streams are mixed in a ratio of 1:2 (or higher in some cases) and then enter the Denitrification zone. The Denitrificaiton zone is composed of plastic media which provides a surface on which the denitrifying bacteria adhere. The denitrifying bacteria convert the Nitrate (NO3) from the recycled flow to Nitrogen (N2) Gas. The BOD in the incoming effluent provides the carbon that is required for the bacteria to grow. This also has the advantage of reducing the BOD load to the aeration zone by approximately 20%.

Aerobic Zone

The combined flows from the Denitrification zone are treated by means of an efficient and compact system (the Aerotor Biozone) requiring minimal power

input and maintenance. It is a combined fixed film reactor and active aeration system mounted on a horizontal shaft.

The rotational media is a spiral formation enclosed in an outer drum to provide active aeration, intense surface area and net hydraulic lift. The Biozone is self-cleansing and no extraneous pumping or sludge returns are required. For process efficiency it is, in effect, a plug flow system.

The BOD is removed to low

levels in the first rotor/s as

carbonaceous bacteria are

more robust than nitrification bacteria. Once the

BOD has been reduced to

low levels the nitrification

bacteria begin to grow on

the remaining rotor/s.

Splitter Box

An important aspect of

treating the effluent down

to low nutrient levels is the

recycle of flow back to the

Denitrification zone.

The splitter box can be adjusted to recycle different

flow ratios depending on

the outlet effluent requirements.

Final Settlement

The Final Settlement or

Humus Tank is a discrete

compartment denying ingress of untreated or partially treated liquor. The

design is similar to the Primary Settlement Tank on

an upward flow basis. This

zone has frequent automatic removal of sludge-to-sludge storage by means of

a timed submersible pump.

It also has a pump designed to return sludge to

the aeration zone to maintain the concentration of

nitrification bacteria within

the Aeration zone.

Sludge Storage

Sludge Storage is provided

in the base of the units.

Depending on the load applied there is approximately twelve weeks capacity

provided. Normally de-sludging is carried out by

suction-tanker.

Sizes available for the Nutrient Removal option are

BL1000NR to BL4000NR.

(100-400 people)

|