NEWS ARTICLE ARCHIVESSandpiper Containment Duty Pump from Kelair Pumps Australia

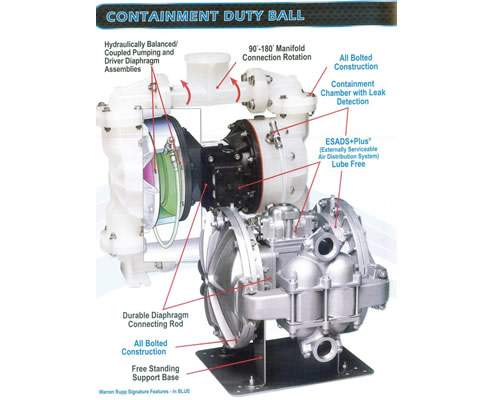

Case Study Sour Water turns to sweet success A major refinery had some problems with an existing magnetic drive pump and contacted Kelair for a solution. The client was pumping Sour Water with fine solids caused by pipe scale. Sour Water is the wastewater that is produced from atmospheric and vacuum crude columns at refineries. The client was using a magnetic drive centrifugal pump. Because Sour water is difficult to seal. sealless magnetic drive pumps are suitable for this application. Also the client was concerned about any external leak, which also suits the magnetic drive pump where the liquid will be contained inside the pump in case of failure. The existing magnetic drive pump was struggling with the scale in the pipe work. Magnetic drive pumps use the liquid being pumped to cool down the magnets through fine internal passages in the pump. The scale in the liquid will start blocking these fine passages which will reduce the cooling of the magnets and cause them to expand and contact each other which will cause total failure of the pump. Kelair's engineer suggested using a Sandpiper containment duty pump which is ideal for highly corrosive and hazardous chemicals. The Sandpiper containment duty pump is exclusively designed with containment chambers to keep accidental spills from entering the air valve, protecting the plant environment and personnel. Also the Sandpiper containment duty pump is designed to accommodate visual, mechanical and low voltage leak detection devices. The Containment duty pump is available in Aluminum, Cast iron, Stainless Steel, Polypropylene and Kynar. Because they were pumping Sour Water, the refinery required Stainless Steel with visual leak detection. The Sandpiper pump is capable of 6.00mm solids-handling which was perfect for the refinery's requirements. Kelair also offered a pulsating dampener to be installed on the discharge side to reduce the pulsation in the line but it was established this was not a problem. Due to the success with the containment duty pump, the refinery purchased an-other pump after four months for a different application. |

|

|