NEWS ARTICLE ARCHIVESIndustrial Lifts for Efficient Site Access from Alimak Hek

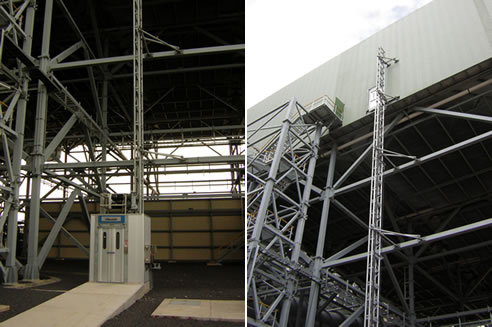

Alimak industrial lifts provide efficient Alimak rack and pinion industrial lifts provide technicians at CS Energy's Kogan Creek Power Station with safe and efficient access to key areas of the site, including emission monitoring equipment on the 160m high chimney stack. Owned and operated by CS Energy, the super-critical Kogan Creek Power Station has set a new standard for coal-fired plant efficiency with the inclusion of an air-cooling condenser (ACC) and chimney stack filtration system. Commissioned in 2007, the Kogan Creek Power Station generates electricity for the national grid 24-hours a day, 7-days a week, providing enough energy to power more than one million homes. Alimak Hek worked closely with CS Energy, and engineering firm Siemens, to incorporate two Alimak SE rack and pinion industrial lifts into the station's air-cooled condenser and chimney stack. Used for everyday maintenance and heavy shutdown periods, the two lifts provide safe vertical access to the power plant, enabling technicians to check emissions monitoring equipment on the chimney stack. Construction of the $1.2 billion power station began in September 2005, with the inclusion of two Alimak industrial lifts specified in the original design: one located in the ACC tower and the other in the plant's chimney stack. Selected for their speed, safety and reliability, the inclusion of the two lifts has helped improve efficiency of access to key areas of the site: the chimney and air-cooled condenser.

The first Alimak lift, an SE 450, was installed on the power station's air-cooled condenser (ACC). The ACC uses air-cooling technology that consumes 90% less water than conventional plants, cooling and condensing exhaust steam after it leaves the turbine for reuse back in the power generation process. Located midway along the structure, the Alimak SE 450 rack and pinion lift was selected to meet operator and design requirements, providing fast and safe access to the 28m high cooling tower. Used for everyday inspections and routine maintenance, the lift is centrally located in the plant to provide optimum access for the station's 90 employees on site daily. As part of the power station's environmental management system, bag house filter technology ensures exhaust gases are cleaned and filtered before being discharged through the chimney stack, reducing greenhouse gas emissions and collecting 99.9% of all fly ash. The second lift, an Alimak SE 300, was selected for installation within the station's 160m chimney stack, to provide technicians with access to the station's emissions monitoring equipment. With safety a major driver in the plant's design, the rack and pinion lift was specified by both CS Energy and Siemens to guarantee the safety of all workers ascending and descending the chimney stack. This emissions monitoring equipment within the chimney stack automatically relays emissions data back to the station's control room. Technicians must routinely check the operating condition of monitoring instruments located on the chimney stack to ensure CS Energy meets its environmental obligations. An Alimak industrial lift provides the safest and fastest means of gaining access to this vital equipment, ensuring the power station maintains its certified environmental standards. Kogan Creek Power Station is certified to the international environmental standard ISO 14001. Installed in 2006, the two Alimak rack and pinion industrial lifts have helped improve plant efficiency and environmental management at the Kogan Creek Power Station by providing reliable access to two of the plant's key structures. Operating under a multi-year service agreement, Alimak Hek service technicians ensure the continued performance and reliability of the two lifts, minimising machine downtime and extending lift life. |

|

|