NEWS ARTICLE ARCHIVES

The Roca ventilated façade systems by Rocks on Hard Surface Solutions

Ventilated façades provide a real ecological skin capable of

adding comfort and beauty to buildings, in tune with the concepts dominating

cutting-edge architecture: sustainability, energy saving, soundproofing and

ease of maintenance.

Roca Ventilated Façade Systems fulfils these and other technical functions

highly valued by building experts, providing:

Energy Saving

Protection is created against changes in outside temperature, ensuring minimal

variations inside the building, with approximate savings of up to 25% on energy

costs.

Good Insulation

The structure of the building is protected from bad weather, with less expansion

and contraction, preventing the emergence of damp and cracks.

Sound Protection

The buildings acoustic proofing is improved.

Excellent Finish

Irregularities in the original building façade are eliminated in using any of

the Roca Ventilated Façade Systems.

Easy Maintenance

Using porcelain tiles as the panels for these systems, allows for minimal

maintenance & ease of cleaning. These panels have a very low absorption, are

resistant to icing and are easy to clean. If required each panel can be

independently removed and replaced - without affecting or altering any other

part of the façade system.

Wear Resistance

High resistance to wear caused by adverse environmental conditions, scapes,

acids and chemical products, etc.

Light Weight

Low in weight, permitting the use of lighter and more economical structures

with less overloading of the building.

Large Panels

The porcelain stoneware panel sizes are up to 600 x 1200mm.

Conservation

The manufacturing & materials used are respectful of natural resources,

and meet all applicable environmental regulations.

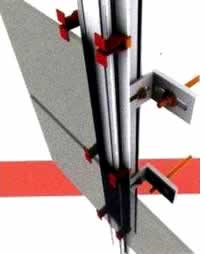

The Roca Ventilated Façade System consists of fitting porcelain stoneware

panels on an aluminium structure that has previously been fixed to an existing

façade or substrate, which does not require special preparation. The porcelain

tile panels are joined to the structure by metal hooks or fixtures, so no

fixing or grouting material is required.

The system is designed for new buildings and for renovation, offering interesting

advantages compared to traditional fixing systems. It can be used for a wide

variety of applications, including houses, blocks of apartments, office buildings,

shopping centres, hospitals, schools and so on. The three types of systems (as

described below) offer many possibilities for achieving all kinds of window, corner

and top crown finishes, allowing you the development of tailormade solutions for

each project.

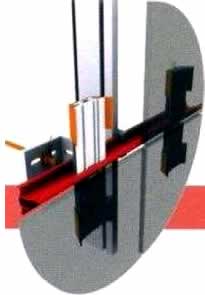

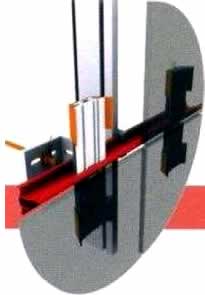

Hidden System

Hidden System

The advantage of the hidden fixing system is that the anchorages used to support

the pieces of porcelain tile panels are not visible from the outside. To achieve

this effect, the panels are machined on the back to accommodate 4 anchorages

needed to hold them to the frame.

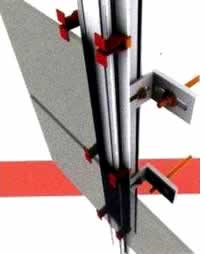

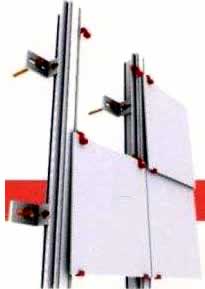

Visible System

Visible System

In the visible fixing system the type of fitting used to hold the porcelain tile

panels to the framework is based on hooks holding the porcelain panels to the

frame. The hooks are made of stainless steel and they can be enamelled in the

same colour as the porcelain tile panels chosen in order to reduce the visual

and aesthetic impact from outside the building.

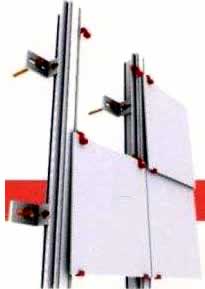

Overlapping System

Overlapping System

The overlapping fixing system, as with the visible fixing system, uses hooks to

hold the porcelain tile panels to the framework. The innovation in this system

allows a scale and curved effect to be created as the façade. The only thing

that can be seen is the lower part of the hook, which is stainless steel and

can be also be enamelled in the same colour as the porcelain panel chosen.

Advantages

The Roca Ventilated Façade System combines design and functionality, providing a

multitude of advantages such as the elimination of risks of flaking and cracking

in the coating, the disappearance of heat bridges and condensed surface water

vapour, the long-term efficiency of the exterior insulation and easy fitting, in

addition to protecting the masonry against the direct action of atmospheric agents

and creating a technical space for installations and piping.

Structure

- Vertical Profiles - extruded aluminium in various sizes.

- Horizontal Profiles - extruded aluminium in various sizes.

- Supporting Stirrup - extruded aluminium in various sizes.

- Anchors - bolts or epoxy resin fixed as required.

- Hooks - stainless steel.

- Springs - stainless steel.

- Nuts & Bolts - stainless steel.

- Gasket Strips - neoprene in various thicknesses.

- Lana Springs - tempered stainless steel.

- Cavity Sizes: The standard distance between the wall and the middle of the porcelain

panel is 145mm, with a standard regulation of + or - 25mm.

Panel Sizes: 400 x 600mm, 600 x 600mm, 300 x 1200mm & 600 x 1200mm.

Panel Thickness: 11 mm.

Panel Finishes: All Rock & Rock, Packstone, Zen and Iron tile material finishes.

Panel Type: Fully vitrified, random glazed porcelain stoneware.

Panel Appearance: Wide variety - including stone, concrete and contemporary.

Panel Production: Double-pressed, rectified edges.

Panel Technical: Water Absorption less than 0.05%.

Surface Hardness - MOHS 8 (of 10).

Frost, Scratch, Chemical and Stain Resistant.

Panel Surfaces: These materials have various surface finishes, textures and

colours that are only comparable to our natural surrounds.

|

Hidden System

Hidden System Visible System

Visible System Overlapping System

Overlapping System