NEWS ARTICLE ARCHIVESRotary Positive Displacement Pumps from Kelair Pumps Australia Pulsafeeder's Eco Gearchem pump

Product News

Considering rotary positive displacement pumps A positive displacement (PD) pump is a general name given to a pump type that doesn't use impellers, but rather relies on rotating or reciprocating parts to directly push the liquid in an enclosed volume, until enough pressure is built up to move the liquid into the pump discharge system. In this article, we look at solutions where rotary positive displacement pumps are favoured over centrifugal pumps due to the need for low flow rate and high pressure. In this case, we'll outline flow rates less than 10 LPM and discharge pressures above 500kPa. In most instances where the required duty for a pump falls within the parameters above and the liquid is thin, one would instinctively consider a centrifugal pump for such an application, more specifically a multi-stage type. But considering such a pump can be problematic. Typically a centrifugal pump operating at lower flow rates and higher pressures would be operating well to the left side of its performance curve. Operating at these areas of a centrifugal pump curve can be difficult when trying to control the flow rate as this area of operation can be very unstable, depending on the steepness of the pump characteristic curve. Pump efficiencies are likely to be very poor and when you take into consideration the End-of-Curve (EOC) run out power, the motor required may be grossly oversized. Let us consider pumping a clean thin liquid, SG 1.1, 5 LPM (0.3 m3/h) and a 60m head as a selection point and the pump must be Stainless Steel in construction.

Considering a popular brand multi-stage centrifugal pump, such a unit has a hydraulic efficiency of 20%, the ab-sorbed power at duty is 0.37kW and the EOC run out power calls for a 0.37kW mo-tor to be installed. The pump speed is 2 pole, 2900 rpm.

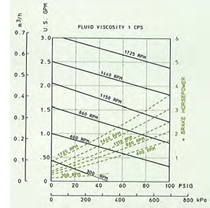

If we now consider a rotary positive displacement pump such as a Pulsafeeder ECO Gearchem pump as an alter-native, the most effective selection is ECO Gearchem pump model G4. At the duty point below, the suggested operating speed for the ECO Gearpump is around 1150 rpm and the maximum power is approximately 0.25 BHP or 0.18kW in metric speak. This is considerably lower than for the comparable centrifugal pump. Clearly the positive displacement ECO Gearchem pump is a more economical option to use for a process application than a centrifugal pump. It is also worth noting that the ECO Gearchem model G4 pump has 1/2" ports whilst the centrifugal pump has 1" ports. The Pulsafeeder ECO Gearchem pumps offer the reliability needed to safely handle clear lubricating and non-lubricating liquids. Extensive material availability provides versatility for pumping low or high viscosity fluids over a broad range of temperatures, pressures, and corrosive services. Inside each ECO Gearchem pump there are two tightly toleranced, machine-generated spur gears consisting of a drive and an idler gear. Self-priming capability is accomplished by closely toleranced gears which evacuate air from the suction piping. Gearchem pumps provide linear, pulsation-free flows, and the pumps are bidirectional. This easily allows the flow direction to be changed. Typical applications for this self-priming, external spur gear include chemical transfer, cyclic operations, continuous production systems, both openend, and closed loop. They are also well suited for pilot plants, vacuum systems, and metering applications. The ECO Gearchem pumps are also available with a range of shaft sealing options which include Teflon and Grafoil packing rings, single and double mechanical seals or Viton Lip Seals. The sealing arrangement allows for easy service or field conversion from one seal type to another without the need for special tools. ECO Gearpumps are available in a range of materials to suit many liquids. The available materials are:

The performance range of the ECO Gearchem pumps are noted below:

These pumps are marketed as the Pulsafeeder Isochem pump.

|

|

|