NEWS ARTICLE ARCHIVESCentrifugal Pump Replaced with Truflo from Kelair Pumps Australia

Case Study Truflo a winning solution for compatibility, and budgetary constraints Kelair was approached to help assist a customer in replacing an obsolete centrifugal pump that was well beyond its working life. The product being pumped was a hot rosin (operating temp at 150°C) used to make various chemicals for the paper manufacturing industry. Some of the other challenges in determining a suitable replacement were:

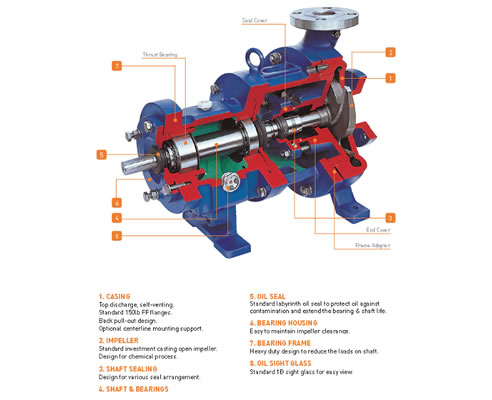

The winning solution was a Truflo 316SS 4x3x13 ANSI bareshaft pump with packed gland shaft seals. Following are the reasons why: It was very difficult to match the dimensions of the existing pump as it had a right-sided discharge port. The most important dimension to match was the 4" suction port as the product viscosity is 150cps. Any size less would potentially make the pump unable to perform to its full capability. As the product temp is 150°C and the viscosity 150cps, an ANSI pump was offered as it is more robust than equivalent ISO and DIN pumps. (Please refer to the cross-sectional drawing for further information). The 4x3x13 with 10" impeller matched the required duty criteria whilst still keeping within the 15kW non - overloading duty requirement. To fit into their tight budgetary constraints, the customer elected to have the pump fitted with a packed gland shaft seal with the fitting of the specialised Eagle Burgmann seal to be done by the customer at some stage in the future. Kelair supplied the pump with a large bore stuffing box. The design, construction and supply of packed gland and gland follower was done by Kelair in-house. |

|

|