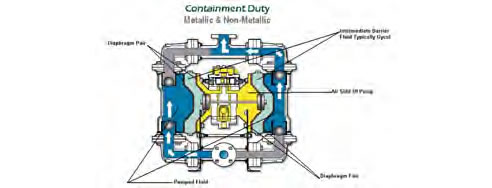

NEWS ARTICLE ARCHIVESDiaphragm Pump by Sandpiper from Kelair Pumps Australia Fig 1

Case Study Very toxic liquid contained by Sandpiper diaphragm pump Kelair was approached by a customer for a pump to unload methanol from a tanker truck. The customer liked the idea of using a diaphragm pump in this application for the following reasons:-

However, the main concern in using a diaphragm pump is what would happen in the event of a diaphragm failure? Methanol is a very toxic liquid with a very pungent odour. Any leakage to atmosphere would be unacceptable. Kelair had the solution to this problem by offering a Sandpiper spill containment diaphragm pump. The spill containment pump works like a standard ball type diaphragm pump except, instead of having a single diaphragm each side of the air valve, it has a pair of diaphragms filled with an intermediate fluid which is typically glycol. In this way, if the driver diaphragm fails, the pumped product leaks into the intermediate barrier fluid instead of the air exhaust (see Fig 1).

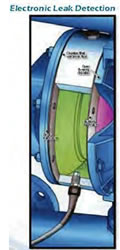

At a point the pumping diaphragm fails, pumped liquid enters the spill chamber displacing driver fluid. The leak detector, working on the principle of conductance, senses the conductivity change. This activates a warning light on the control box. The device can also be wired into the pump user's existing system, for an audible or visual alarm, or pump shut-down response. It is important to specify an appropriate drive fluid which is both chemically compatible with the pumped fluid and displays the opposite conductance properties. Polarity of the leak detector can be set to sense conductive or non-conductive fluid. If a leak occurs, pumpage is contained in the spill chamber. The pump will continue to work, and in many cases, repairs can be done when the batch is completed. The air valve and work environment are protected.

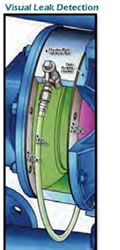

At a point the pumping diaphragm fails, pumped liquid enters the spill chamber, displacing driver fluid. The exchange of pumpage and driver fluid displays a colour change in the sight tube, giving a visible signal. Driver fluid should be chemically compatible with the pumped fluid, with an obvious difference in colour. In the event a leak occurs, pumpage is contained in the spill chamber. The pump will continue to work, and in many cases, repairs can be done when the batch is completed. The air valve and work environment are protected. |

|

|

Electronic Leak Detection

Electronic Leak Detection

Visual Leak Detection

Visual Leak Detection