NEWS ARTICLE ARCHIVESAlbin Hose Pump for Mining Upgrade from Kelair Pumps Australia

Case Study It's gold with Albin hose pump for mining upgrade Kelair received an enquiry through a consulting engineering company for a pump package for a gold mine upgrade. A hydrochloric acid dosing pump was included in the package and the duty requirements were:

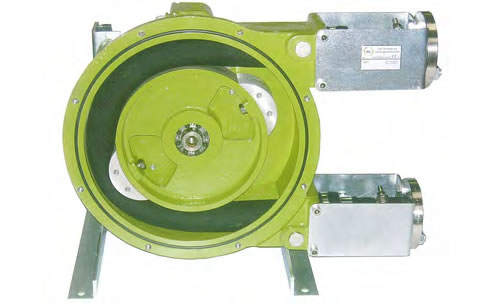

While the original specification was an air operated diaphragm pump, the client had issues with the noise, reliability and dosing accuracy of an air operated diaphragm pump and instructed Kelair to provide electric drive alternatives. Kelair's engineers looked at several options; a helical rotor was unacceptable because exotic materials would be required to manage the HCl solution and the pump has a mechanical seal, something the engineers wanted to avoid in this application. Kelair offered two solutions; the first was an OBL simplex (1 pump head) diaphragm metering pump with non-metallic head and valves. The pump would be fitted with stroke actuation, so flow could be adjusted via a 4-20mA signal. The second option was an Albin hose pump where flow would be adjusted by speed control via a variable frequency device (VFD). The diaphragm head metering pump is the more accurate of the two, but has some drawbacks. The stroke control requires a 240v (single-phase) supply while the motor is 415v (three-phase), so effectively the pump requires two power sources. Also having a stroke controller on the pump put electronic controls outdoor, into a bunded area on a mine site. This is traditionally regarded as a tough environment. The Albin hose pump delivers a fixed volume of liquid per rotation. There is no slip in a hose pump which makes them ideal for applications where absolute accuracy is not the primary concern. Where the hose pump did win hands down was in simplicity and robustness of design and operation. The Albin pump is in ductile iron construction with very few moving parts and no seal, valve balls or diaphragms. The acid is squeezed through a hose and the only wetted parts are the EPDM hose and the polypropylene inserts used to connect the suction and discharge to the pump. While dry-running and self-priming were not required in this application, the Albin hose pump can do both. A 25mm ALH25 pump running at 48rpm was selected which is capable of delivering the 0.8m3/hr continuously. The selection is quite conservative and will result in long hose life. The pump was fitted with a SEW reduction box and TECO 0.75kW mine specification motor on an Albin pump frame. The Albin hose pump had a lower initial cost than the diaphragm head metering pump and has proved reliable in operation, and in the year since its installation, has required no spares or maintenance. |

|

|