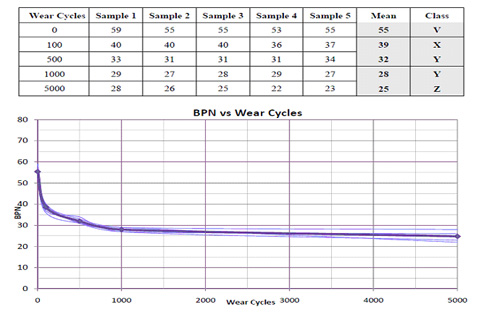

NEWS ARTICLE ARCHIVESWearMax clear anti slip coating from Global Safe Technologies The maintenance manager of this Australian media icon was shocked when saw the report of their regular annual independent slip resistance testing, of the bathrooms floors where new tiles were laid just 9 months earlier. The wet pendulum test of the surface has shown a mean (British Pendulum Number) BPN 28, which meant that the tiled surface was not only under the relevant slip resistance standard recommended value of BPN 35 or above (Class X), but also greatly increased the risk of a slip and fall incident. This result was especially dramatic as the new tiles before installation were rated to a considerably higher value of BPN 55 (Class V). Global Safe Technologies were called to investigate and reason and to rectify the issue. The consultant attended the site and observed that bathroom surface was very well maintained with no excess chemicals on the surface and no mechanically aggressive cleaning method was employed - surfaces were mopped - , so cleaning could not cause such a dramatic deterioration of the surface slip resistance. Alternative reasons like application of inappropriate surface sealing product was also discarded. Then the consultant suggested that the tiles be submitted to accelerated wear test to find out whether they just simply worn out. Safe Environments was engaged to conduct the accelerated wear test which has provided some very surprising results and also give an explanation of the gross reduction in slip resistance. The table and graph below shows the test results. As a result, Global Safe proposed that its environmentally friendly, sustainable WearMax clear anti slip coating solution be installed onto the existing tiled surfaces which were independently tested after installation to show a compliance with relevant slip resistance standards. Currently accepted interpretation of the result, that 5000 cycles means that it may be from 2 years onwards and is speculative at this stage. It is generally stated that 100 cycles equates to about 6-8 weeks use, 500 cycles to about 6 months to 1 year use, 1000 cycles 1-2 years use and 5000 cycles about 2 years+. The accelerated wear test while is NOT an exact indication for ALL environments and situations, but will at least give an indication of expected useful life of the pedestrian walking surface. This result also has shown that high initial slip resistance does not mean sustainable slip resistance and pure reliance of a single slip resistance result can provide some very unpleasant surprises. This specific example is not the only one. Other accelerated wear test results by Safe Environments, have occasionally also shown very rapid reduction of slip resistance of the tile being tested. So, how can be ensured that a tile or any other surface will provide sustainable slip resistance? Architects, specifiers, builders and other purchasers prior to committing themselves to a specific product should not simply rely on a slip resistance test, but also should insist on an accelerated wear test of the proposed surface. Having an accelerated wear test will provide several advantages, namely;

Another important issue that apart from very specific environments - oil contaminated and wet bare foot traffic - the slip resistance specification should specify not only an initial, but a sustainable Wet Pendulum rating of the proposed surface, not a Ramp rating. It is also strongly recommended that after installation of a surface independent slip resistance test be performed and be part of the overall documentation. Global Safe Technologies has almost its entire solution range accelerated wear tested. The company being the industry leader, also provides independent slip resistance testing after installation to commercial clients as an integral part of any floor safety solution at no additional cost**. This test result being art of the overall handover documentation, will give assurance to the client that the solution provided is fully compliant with relevant slip resistance standards. ** Minimum surface safety solution value applicable to have free slip resistance test. When surface safety solution value is small slip test will be provided at an additional cost. |

|

|