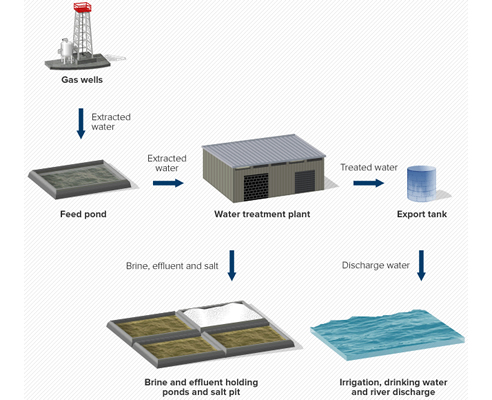

NEWS ARTICLE ARCHIVESPVC Pipes Save Millions in Costs from Think Pipes Think PVC Using PVC pipes to save Millions on CSG Water Pipeline Infrastructure Costs. Coal seam gas production is water hungry business. Millions of gigalitres of water are brought to the surface, removed from the coal seam in order for the gas to be extracted. Conservative estimates suggest coal seam gas wells could draw 300 gigalitres of water from the ground each year from the some 40,000 coal seam gas wells estimated for Australia. Once the water is brought to the surface, it needs to be transferred via a vast network of underground water pipes to large feed ponds on mining tenements. Large Diameter PVC pipes are the most cost effective material to build underground water pipes to get water from the gas fields to the water treatment plants, often located more than 50 kilometres away. PVC pipes potentially offer a 20% cost reduction in building water pipeline infrastructure over PE pipes in sizes ranging from 500 - 800mm. PVC pipe is also the best option for distribution of treated water back to the environment after the treatment plant. Besides its cost advantage, PVC is the best performing, most sustainable and the safest option for water infrastructure. |

|

|