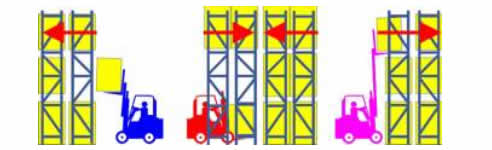

NEWS ARTICLE ARCHIVESDrive In Racking Sydney from Speedrack Drive-In racking is used where high-density storage is required. It is frequently used in facilities with a low number of product lines. Pallets are stored in a block system with a reduced number of aisles. Fork-lifts drive into the racking between uprights to load or retrieve pallets. The first pallet in is the last one out. Drive-In Racking is ideal for;

Drive-In Racks allow a forklift to enter the rack from one side to pick up or pull out pallets. This is done because pallets can slidebackwards on a continuous rail. Forklifts drive into the rack to access pallets. This is a last-in, first-out arrangement for your pallets. Drive-In Racking can be used by any forklift trucks. Self centering rails automatically position pallets quickly and safely. This ensures that pallets are presented correctly to the operator, promoting safe handling, ease of use and reducing damage to the rails and uprights. Drive-In Racking offers the ability to store a large amount of similar loads in a smaller area. Selectivity is sacrificed, but storage density is outstanding. Drive-In Racking can store up to 75% more pallets in the same space than selective racking. It requires fewer aisles and has better cubic storage.

|

|

|