NEWS ARTICLE ARCHIVESFood Grade Pumps from Kelair Pumps Australia

Case Study Sandpiper pump soft on cooked vegetables Kelair Pumps was contacted by a major food manufacturer to supply a food grade pump. The most important requirements of the pump were that it would handle soft solids, such as cooked vegetables, without damage to the overall presentation and that the pump should be able to run dry. Visiting the site and listening to the customer's requirements, Kelair's sales engineer suggested a Sandpiper FDA approved flap-valve pump. The flap valve fitted pump has the advantage over a ball valve fitted pump in that it can handle much larger solids. The solid shandling capability of a conventional ball valve-operated pump is determined by the following clearances within the pump:

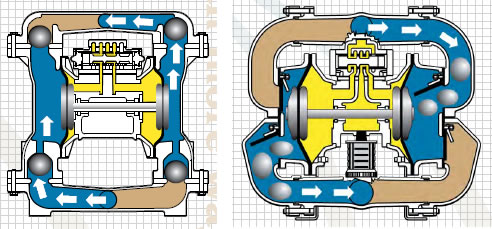

The customer was advised that the valve ball would damage the soft solids when it would seat itself on the valve seat. The pictures show the two different pump designs and in addition to the different valves, one sees instantly that the pumps have opposed product flows. Where the suction on the ball valve pump is at the bottom of the pump, the flap valve pump has the suction on the top. What is the logic behind this? To understand we have to go back to when the flap valve pump was designed. Initially the inventor had in mind to design a solids-handling pump for the mining industry. Ball valve operated pumps when used on liquids which have lots of solids such as rocks etc, in suspension failed constantly. The reason was that if the pump was turned off, the solids would fall out of suspension and drop into the bottom of the wetted pump chamber. Then as soon the pump was started again, the solids were compressed by the outer diaphragm plate and the diaphragm itself. This resulted in diaphragm failures, broken diaphragm plates and even bent shafts, because it is very difficult to bring the heavy solids upwards in the chamber due to gravity working against this. In comparison, when a flap valve pump is stopped, any solids left in the liquid chamber settle out into the discharge manifold. The Sandpiper flap valve pumps are designed so that a 2" pump can pass 2" solids. The supplied pump is food grade which is FDA-approved. The wetted material is of 316 stainless steel and the diaphragms are manufactured from food grade Santoprene. After trialling the pump for three months the food manufacturer is very satisfied. The pump is used now not only on soft solids but other applications as well. Also, since the customer can control the start/stop of the pump via the discharge and because the pump can run dry indefinitely without damage, this has resulted in an additional two pumps being ordered. |

|

|