NEWS ARTICLE ARCHIVESImprove Thermal Performance with Wall Wrap XP from Bradford

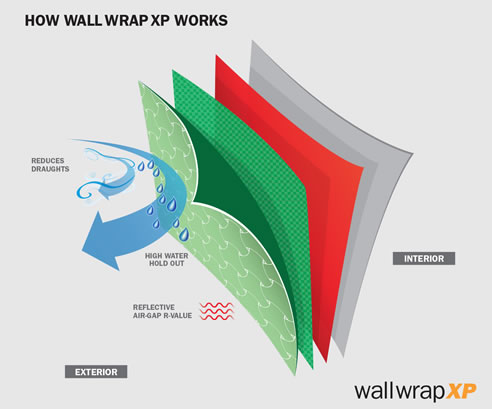

Bradford Thermoseal™ Wall Wrap XP UNDERSTAND THE XP DIFFERENCE When the building stud cavity is filled with wall batt insulation, conventional (single sided inward facing) wall wraps are no longer able to contribute an additional air-gap R-Value to the wall system. Thermoseal Wall Wrap XP overcomes this problem by using an outward facing patterned antiglare surface to allow you create a more energy efficient wall system by boosting the performance of your wall batt insulation.

KNOW THE BENEFITS - Provides an air-gap R-Value even when the wall insulation is in contact with the wall wrap - conventional wall wraps only provide an R-Value contribution when the stud cavity is empty. - Allows reduction of wall insulation or incremental increase in wall insulation performance - the tables on the next page highlight the significant performance gains you can achieve. - all Wrap XP is constructed from a lightweight polymer which is tough and complies to the BAL ember standard, so you can use it in bush fire prone areas with confidence. THERMAL PERFORMANCE Wall Wrap XP typically provides up to an additional RT0.5 contribution* to the wall system when compared to a conventional wall wrap with wall insulation batts positioned in the stud cavity. Simply select the relevant construction type and wall insulation from the table below, then compare the summer and winter performance improvement.

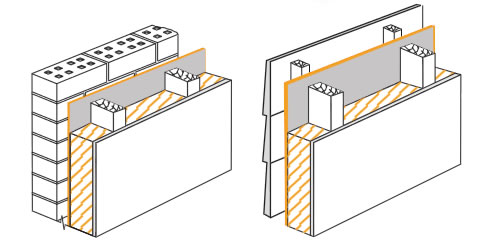

BRICK VENEER Construction: 40mm brick cavity - with Wall Wrap and wall batt insulation in a stud frame as noted below, plus 10mm Gyprock™ internal lining. LIGHTWEIGHT CLAD Construction: Fibre cement cladding with 25mm batten - Wall Wrap and wall batt insulation in a stud frame as noted below, plus 10mm Gyprock™ internal lining. |

|

|