NEWS ARTICLE ARCHIVESViking Pumps in Tallow Process Beneficial to Environment by Kelair

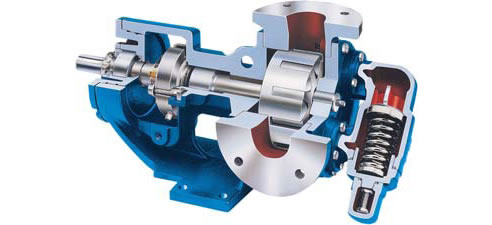

Case Study One of Kelair's customers creates large amounts of waste vegetable oil and animal fats. This article explains the basic process of how the tallow operation creates biodiesel and its benefits to the environment. Viking gear pumps play a major role in this process. How it works is that a portion (10% of the tank) of the waste oils/fats are pumped from a tank and circulated through a recirculating loop containing heat recovery. This heats the oils/fats to produce a vapour/liquid. After this has occurred the vapour/liquid is returned to the tank. This continues until the whole tank has been through the heat cycle. The liquid can now be drained and this is done through the bottom of the tank with a controlled rate of flow determined by the Viking pump into what's known as columns. These columns have packing around them known as nutter rings. These control the temperature of the liquid and the product leaves the column as vapours. The gases pass through an air-cooled tube condenser where the temperature is reduced and the product returns to a liquid state. From there a Viking pump transfers the liquid into a flash vessel which is fitted with two electric heaters. This lowers the flash point of the product as well as flashes off the light ends including water vapour and naphtha product. The products are now transferred using another Viking pump through another flash pot and then discharged into a storage tank. This process can happen one to three times depending on what quality level is required of the biodiesel. The benefits in doing this include the following:

In conclusion tallow operations creating biodiesel are a long process and not economical compared to mineral diesel but the benefits to the environment are many. |

|

|