NEWS ARTICLE ARCHIVES

Energy Rating Wall Wrap XP in BERs Pro from CSR Bradford

ENERGY RATING IN BERS PRO®

TECHNICAL GUIDANCE FOR THERMOSEAL™ WALL WRAP XP

When modelled correctly, reflective laminate wall wrap products can contribute an additional air-gap

R-Value to a wall system, improving the overall thermal efficiency of the home. To ensure that the additional

air-gap R-Value is correctly calculated, this Building Knowledge Series by CSR Building Products provides

guidance on how to accurately input Bradford Thermoseal Wall Wrap XP into BERs Pro.

PRODUCT SPECIFICATION

Thermoseal Wall Wrap XP has a reflective and non-reflective surface with the following properties:

- The reflective surface faces outwards and has an emittance of 0.09

- The non-reflective surface faces inwards and has an emittance of 0.9

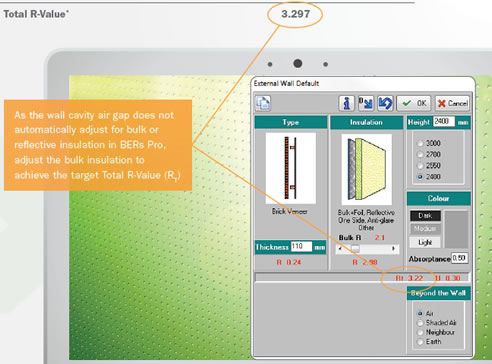

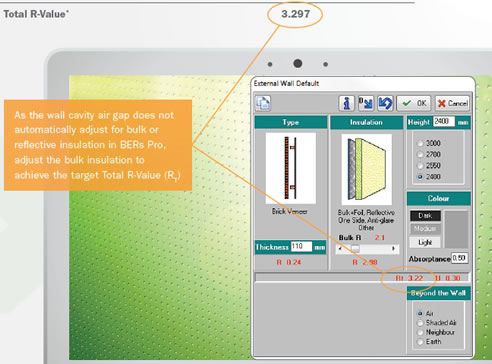

BRICK VENEER CONSTRUCTION EXAMPLE

This example uses a Brick Veneer wall with a 110mm extruded brick,

Thermoseal Wall Wrap XP, R2.5 wall batts and 10mm plasterboard lining.

- Layer 1: Contains the 110mm extruded brick 0.18

- Layer 2: Select 40mm 0.09/0.9 reflective air gap 0.558

- Layer 3: Select R2.5 wall batt 2.5

- Layer 4: Select 10mm plasterboard 0.059

Total R-Value* 3.297

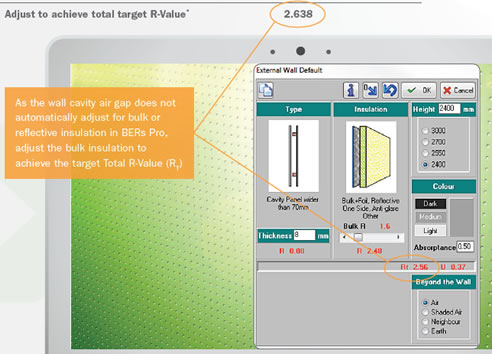

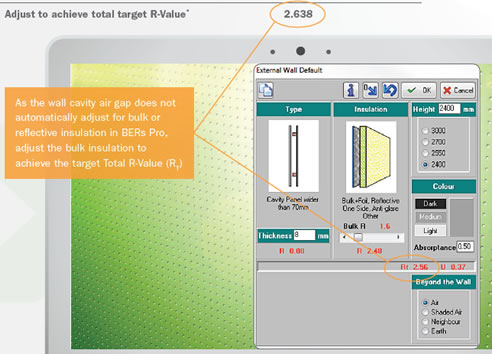

SIMULATION SPECIFICATION

To simulate this product in BERs Pro use the Calculation Tools available to firstly work out the R-Values of all the elements.

Once you have these values you can then work out the wall Total R-Value. In External Walls select 'Bulk + Foil, Reflective One

Side, Anti-glare Other'. Then modify the bulk insulation R-Value so that the Total R-Value of the wall is equal to (or under) the

Total R-Value worked out by using the Calculation Tools. The examples in this document will guide you through this process.

LIGHTWEIGHT CLAD CONSTRUCTION EXAMPLE

This example uses a 9mm Cemintel™ Expresswall™ panel on a 35mm top hat,

Thermoseal Wall Wrap XP, R2.0 wall batts and 10mm plasterboard lining.

- Layer 1: Contains the 9mm Cemintel Expresswall panel 0.028

- Layer 2: Select 35mm 0.09/0.9 reflective air gap 0.551

- Layer 3: Select R2.0 wall batt - adjust to achieve the

- required total R-Value (RT) 2.0

- Layer 4: Select 10mm plasterboard 0.059

Adjust to achieve total target R-Value* 2.638

THERMOSEAL WALL WRAP XP - UNDERSTAND THE XP DIFFERENCE

When the building stud cavity is filled with wall batt insulation, conventional (single sided inward facing) wall wraps are no

longer able to contribute an additional air-gap R-Value to the wall system. Thermoseal Wall Wrap XP overcomes this problem

by using an outward facing patterned antiglare surface to create a more energy efficient wall system by boosting the

performance of the wall batt insulation.

|