NEWS ARTICLE ARCHIVESSandpiper Food Grade Pumps from Kelair Pumps Australia

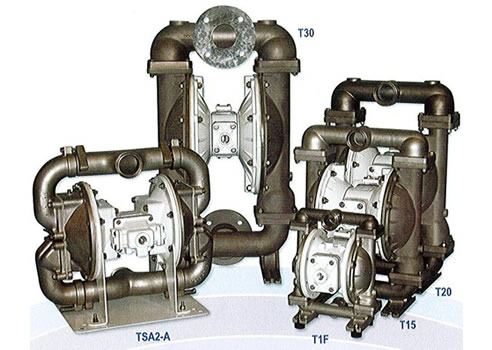

Case Study Hazardous problem resolved with Sandpiper food grade pumps A customer recently re-evaluated the designated hazardous areas in their factory. Those around the bottle filling areas were reclassified Zone 2 IIA T2, due to the presence of ethanol in the products. As a consequence, pumps on the wasting lines on the filling machines were earmarked for replacement as the pumps were close-coupled electric units whose motors did not comply with the new hazardous area designations. The customer recommended that the hazardous area consultant contact Kelair to assist with the new pump selection. A Kelair sales engineer visited the facility and worked through the problems with the consultant. The engineer identified two potential problems in addition to the hazardous area designation; there were no low tank level sensors that would prevent mechanical seal damage on an electric pump when there was no liquid in the supply tank (a problem confirmed when maintenance engineers mentioned that the existing pumps have problems due to dry running); the wasting lines were automatically CIP cleaned, so the proposed pump would have to be CIP capable, and be able to handle the CIP liquid pressure of about 2 bar at the pump inlet. The application was tricky, as the customer did not want to put in new sensors - which would also have to be rated for the hazardous area designation - and also specified that a food grade pump must be used. However, Kelair's engineers resolved the problem using Sandpiper's T15 air-operated double diaphragm (AODD) pump. The T15 model AODD pumps form part of Sandpiper's comprehensive food grade pump range. The T15 is FDA-compliant, CIP-capable, constructed from 316-grade stainless steel wetted parts, FDA-approved Santoprene ball valves and diaphragms (to allow caustic to be used when cleaning), a fully bolted design for easy disassembly and Sand-piper's lube-free, non-stall, ESADS air system. All Sandpiper pumps are available as ATEX-certified, which the hazardous area consultant accepted as suitable for the area. They have no problems with dry running, so no low level sensors were required. All AODD pumps have problems with high inlet pressures, because if the pressure on the wetted side of the diaphragm is over 1 bar greater than the pressure on the air valve side, then the diaphragm will be pressed hard into the centre section, resulting in diaphragm damage or even immediate diaphragm failure. Kelair's engineers solved this problem by installing a special back pressure valve on the exhaust side of the pump's air assembly which ensured that the pressure inside the centre section was always high enough to prevent a pressure differential of greater than 1 bar across the diaphragms. The CIP procedure could now be run without the pumps being damaged. The consultant and customer were very pleased with the solution presented by Kelair, and all the electric pumps marked for replacement were replaced with the Sandpiper T15. |

|

|