NEWS ARTICLE ARCHIVESSandpiper Spill-Containment Pump from Kelair Pumps AustraliaSpill-containment supports safety

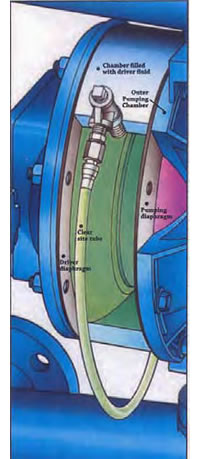

A major Victorian Hydrocarbon processingcompany was using a conventional diaphragmpump for tanker unloading. Thiswas always a concern to the company becauseif one of the diaphragms ruptured,methanol would be released into the atmosphereand this would create two major problems: 1. Potential for the product to come intocontact with the operators. (Methanol ishighly toxic and when inhaled is a majorhealth hazard). 2. Highly Flammable. The release of methanolinto the atmosphere may cause an immediatefire explosion. The other complexityis that when methanol is on fire it maynot be readily visible. In overcoming these two hazards the client wassold on the Sandpiper spill-containment pump. This pump design consists of a pair of diaphragmslocated at the side of the air distributionvalve. Between each diaphragm pairthere is a barrier fluid. The advantage of thisdesign is that should the inner diaphragm rupturethe product would leak into the barrierfluid and not the outside atmosphere. Conventionaldiaphragm pumps only have a singlediaphragm and no barrier fluid. In the case of this customer, the barrier fluid isglycol which is green in colour and if there wasa rupture, it would be picked up by a colourchange in the clear visual indicator tube. |

|

|