|

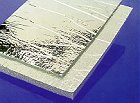

SOUND SORBER WITH METALLISED FILM

Soundsorber foam is an acoustic grade polyurethane foam with a metallised polyester facing. Sorber/MYL is designed

to obtain maximum sound absorption per given thickness through the uniform cell structure of the polyurethane foam. |

|

The metallised facing offers protection against petrol, grease, oils etc, and also enhances the acoustic characteristics

in the low frequency range.

Application:

Sorber is a highly effective sound absorber with a tough flexible and impermeable surface for applications such

as generators, enclosures, compressors, engine compartments, bus, truck and car under bonnets insulation, hydraulic

pump enclosures, marine engine compartments and duct linings.

|

Benefits

- Excellent acoustic absorption properties

- No irritating fibres or dust particles

- The standard pressure sensitive adhesive (PSA) used has good chemical and weather resistance while giving effective

adhesion over a long period when applied to clean dry surfaces

- Vibration resistant

- Impermeable to dust, grease, oil, petrol and any other fluids

- High tear resistant surface

- Ignition retardant (test report available)

- Easy to cut, bend and install

- Resistant to UV, ozone & chemical attack

- Australian made

|

Options:

- Hydrolysis resistant polyether polyurethane foam is recommended for areas in contact with exhaust fumes, moisture

or humidity

- All sorber foams can be supplied with a pressure sensitive adhesive (PSA) backing

- The standard PSA used exhibits initial tack and adhesion to clean dry surfaces and provides high shear &

heat resistance

- A polyurethane sealer is available for exposed edges

- Other surface or colour finishes

- Soundguard offers facilities for die cutting and CNC fabricating to customer requirements

- Soundguard products are available from 3mm to 100mm thick

- Soundsorber foams can be combined with barrier and dampening layers to improved their acoustic performance.

|

Specifications: |

|

|

| Part Number: |

SORB/NA (Foam thickness) / MYL |

| Thickness: |

6mm, 12mm, 25mm, 50mm standard

(non standard thicknesses available on request) |

| Width: |

1400mm - 0, + 20mm |

Density:

(AS2281) |

28.0 - 30.0kg/m3 |

Noise Reduction Coefficient:

(AS1045) |

Refer to appropriate test report, ATF511 - NRC 0.50 for 25mm foam

ATF509 - NRC 0.85 for 50mm foam ATF509 - NRC 0.85 for 50mm foam |

Percentage Recovery:

(AS2281) |

60% (min) |

Tear Resistance (N/M):

(AS2281) |

520 (min) |

Tensile Strength (kPa):

(AS2281) |

175 (min) |

Compression Set: (75%)

(AS2281) |

20% (minimum)

15% (maximum) |

Cell Count / 25mm:

(AS2281) |

55 +/- 5 |

| Surface Finish: |

Metallised polyester |

| Colour: |

Metallic Silver |

| Chemical Resistance: |

Excellent resistance against common solvents, water, acids, alkalies |

Service Temperature:

(Foam) |

100°C Continuous

130°C Intermittent |

Thermal Conductivity:

(30kg/m3 foam) |

0.033 W/Km |

Pressure Sensitive Adhesive:

(PSA) |

Modified Acrylic |

| PSA Temperature: |

Maximum Continuous 93°C

Maximum Intermittent 107°C |

|

*Surface preparation - when using PSA or contact adhesive, it is essential

that the surface be clean, dry and free of grease and oil.

|