|

SOUNDSORBER BARRIER

MARINE - TRUCK - BUS - TRAINS - ENCLOSURES

MAXIMUM performance

Noise control can be a complicated business, sometimes it requires a transmission loss barrier and at

other times an absorber to soften the noise and control any reverberant noise build up, and there are times

when the problem requires both of these approaches to achieve the best result.

This is where Pyrotek's range of composite barrier/absorber materials come to the fore as they are designed

to deal with these situations in the most effective and economical way. Applications like compressor, generator

or plant rooms, mobile machinery cabins and marine craft engine rooms all need this treatment to ensure the well

being of those in the enclosed area, as well as those outside of it.

The decoupled high mass barrier layer ensures maximum reduction in the transmission of the sound wave through

the structure to which it is attached while the hydrolysis resistant acoustic foam material reduces the noise effect

and any reverberant noise build up within the enclosed space by absorbing the airborne sound waves.

|

Soundsorber Mat

Is designed to achieve maximum attenuation over a broad frequency range. The combination of dense, flexible

load vinyl barrier with foam provides a total noise control system. This product range offers a variety of facings

that can be applied to the surface of the barrier to increase the durability and weatherbility.

When Soundsorber Mat is used in wet areas, as in marine or truck cab application, closed cell foams can be used. |

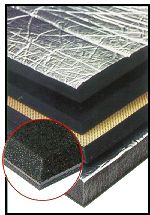

Soundsorber Barrier

Is a composite product comprised of two layers of acoustic foam (SoundsorberT) and a single flexible

barrier.

This composite is designed to provide maximum noise reduction in the hardest environment. The isolation foam (6mm

thick) decouples the flexible barrier from the substrate while the thicker absorbing foam (SoundsorberT) reduces

the airborne noise.

Soundsorber Barrier is available with various foam thicknesses and surface coverings to accommodate any circumstances

while still maintaining its excellent acoustic performance. |

|

|

Benefits

- Hydrolysis resistant foam out lasts conventional acoustic foam three fold.

- Highly flexible barrier layer equals high transmission loss.

- Flame resistant surface layer, recommended for marine use.

- Unique manufacturing technique ensures total fusion of the foam to the barrier.

- Excellent noise reduction per given thickness of product.

|

Options

- A variety of surface coverings to suit any application.

- High performance pressure sensitive adhesive backing, exhibits excellent initial tack and adhesion to clean

dry surfaces and provides high sheer and heat resistance.

- A polyurethane sealer is available to seal any exposed edges.

- Soundguard offers facilities for die cutting and fabricating to customers requirements.

- Can be supplied in rolls or convenient sheet size.

|

Installation

These composites can be adhered to the substrate with factory supplied pressure sensitive and adhesives

for temperatures up to 120°C. It is recommended that a contact adhesive "Soberbond" or mechanical

fasteners (hanger pins) be used for these heavy loaded composites in overhead applications.

These products can easily be cut with a sharp knife and can be die cut into any complex shape. All products can

be supplied in convenient sheet or roll sizes. |

Product Specifications

|