|

WAVEBAR - Flexible noise barrier

|

The easy way to reduce noise through walls, floors and buildings near airports; as strip curtains, soft machine

enclosures and truck mats; and for muffling explosions and noisy equipment such as jack hammers, drill rigs and

pile drives.

Made of special barium-loaded material, Wavebar

is very flexible and easy to install even in and around

awkward places or drape - or join into mats and enclosures - to greatly reduce noise transmission.

A variant, Wavebar Quadzero, is manufactured with an aluminium finish. |

|

|

Features and benefits

Wavebar

...

- is easy to cut and fabricate around pipe penetrations, ducting and cabling

- boasts high tensile strength

- is highly resistant to tearing

- is highly chemically resistant to oils, alkalis and acids

- enables unusually long vertical drops, providing an economical noise-barrier system even where space is limited

- comes in weights of 2, 4, 6, 8 and 10 kg/m²

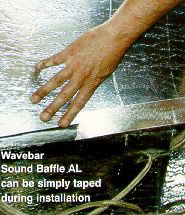

- in its Wavebar

Quadzero variant, is suited to joining with aluminium-reinforced tape thereby eliminating the

need to use adhesives or mechanical fastening.

Applications

Wavebar

is ideal for:

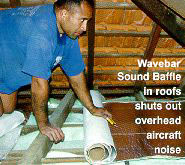

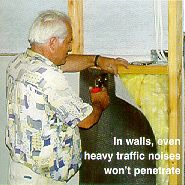

- shutting traffic and aircraft noises out of offices and homes

- portable screens

- use in partitioning

- under floor

- above false ceilings

- soft enclosures for fans and machines

- strip curtains

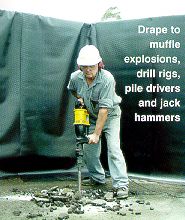

- use as a sound barrier against the noise of jack hammers, drill rigs, blasting and pile drivers.

- truck and bob-cat mats.

Specifications

- Construction: 100% polyester fabric & barium loaded vinyl

- Weights: 2, 4, 6, 8 and 10 kg/m²

- Roll widths: 1350mm

- Roll lengths: Up to 20 m

- Roll weights: All rolls exceed 30 kg and must be handled by at least two people

- Specific gravity: 2.2 g/cm³

- Flammability: Self extinguishes on removal of flame. Also meets the "Four Zero" early fire

hazard index laid down in AS1530.3 (1989) - Simultaneous determination of ignobility, flame propagation, heat

release and smoke release, which is a requirement under the Australian Building Code.

- Sound transmission loss: Achieves Rw 30 with a CAC (ceiling attenuation class) of 50 in a single flexible

layer as determined by independent tests conducted to AS1191 Acoustics - method for the laboratory measurement

airborne sound transmission loss of building partitions by National Acoustic Laboratories.

|

|

|

Installation

|

Step 1:

Assess the area where the baffle is to be fixed.

Make sure the ceiling slab is level when fixing the C-track or timber batten. If the slab is not level, fill the

area with a caulking compound.

|

Step 2:

Cut Wavebar to fit. To do this, first measure the height between the ceiling and the ceiling

slab (h).

Add the width of the C-track or batten and add a minimum of 250mm for the ceiling overlap.

Thus, in the schematic, the length (L) you would need to cut is given by L=h+100+250.

|

|

Step 3:

At joins, overlap Wavebar

at least 50mm. Join the overlap with screws at 100mm intervals.

Alternatively, if using Wavebar, use 75mm wide reinforcing tape to join the overlap down the full length

of the drape.

|

Step 4:

For pipe, cable and ducting, measure and mark out the appropriate diameters or other dimensions

and make incisions in the Wavebar

to allow the obstructions to pass through. Using Wavebar for this

work is recommended because of its ease of tapping.

|

|