Stainless Steel Pot Washers: Power Soak® from Stoddart Manufacturing

The Power Soak® range of stainless steel pot-washers from Stoddart Manufacturing are the most efficient, most installed continuous motion pot-washers worldwide. The Power Soak® pot-washers are the only unit with back-of-the-tank-jets.

The Power Soak® as pot-washers or dishwashers have been proven to have uniform wash action. The jets create a continuous pot-washing action.

Stoddart Manufacturing has sold Power Soaks into Major quick-serve Restaurants, Sports Stadiums and many of our nation's large hotels.

The Power Soak® pot-washers are available in various formats and sizes, this is to suit many different application and uses.

Features & Benefits:

- Constructed from 304 Stainless Steel

- Helps reduce clients pot and pan wash up labor cost by up to 50%

- Powers Soaks do not require air extraction or induction over them

- The wash tank is heated to 45°C, to soften and remove baked on grime

- The unit will clean more efficiently than a mechanical style pot and pan washer

- Power Soak® owes it efficiency and success in the worldwide market to its Patented Features:

- Fully self draining stainless steel pump to minimize the risk of legionnaire's disease

- Its rolling action that is due to the back-of-the-tank-jets.

- Due to the continuous flow employees are able to complete other tasks

- Continuous heavy-duty (TEFC) motors (high service factor) are provided with all pump assemblies.

- Complies with Australian Electrical requirements AS NZS 60335.1, AS 3000, AS 3760.

- Complies with Sydney Water trade waste guidelines'.

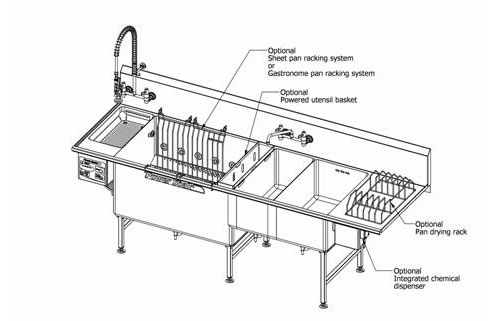

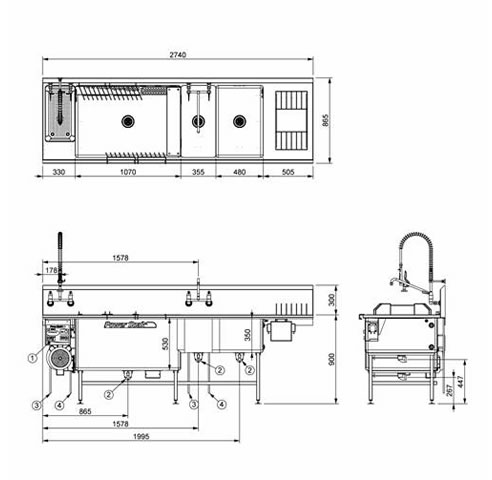

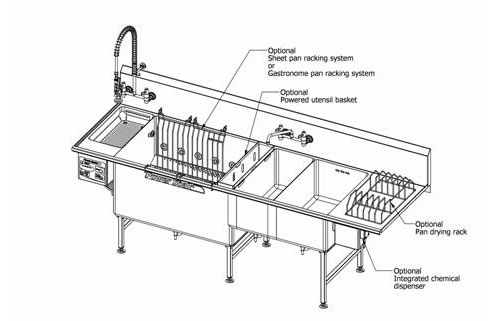

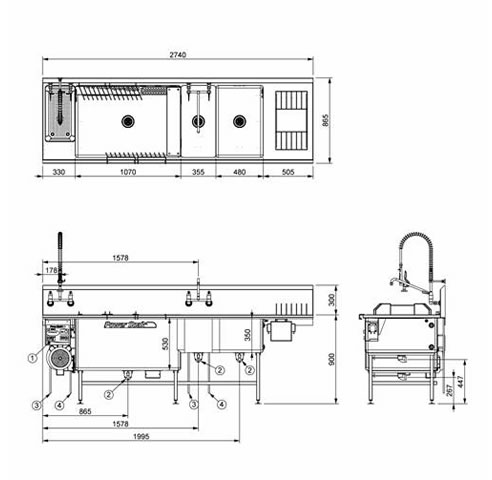

Drawing of a SPPS-108L-P2-415 Power Soak:

- Pre-scrape Tray

- Wash Tank with the back-of-the-tank-jets

- Rinse and Sanitize Tanks

- 1 Electrical Connection: 3 Phase + N +E 415v 16amp(Single Phase 240v 20amp)

- 2 Waste Connection: 2" BSP Male

- 3 Waste Connection: 1 1/2" BSP Female

- 4 Water Connection Hot: 1/2" Copper

- 5 Water Connection Cold: 1/2" Copper

- Pot and pan Drying Rack

|

Bus Shelter Manufacturer QLD by Stoddart

Bus Shelter Manufacturer QLD by Stoddart Freestanding Foot Operated Wash Basin by

Freestanding Foot Operated Wash Basin by Refrigerated Food Display for

Refrigerated Food Display for Wand Operated Wash Basin by Stoddart

Wand Operated Wash Basin by Stoddart Ductless Exhaust Hood for Kitchens by

Ductless Exhaust Hood for Kitchens by Tile Insert Floor Trough by Stoddart

Tile Insert Floor Trough by Stoddart Architectural Metal Staircases by

Architectural Metal Staircases by Outdoor Shower for Beaches by Stoddart

Outdoor Shower for Beaches by Stoddart Undercounter Dishwasher for Kitchens by

Undercounter Dishwasher for Kitchens by Heated Food Display by Stoddart

Heated Food Display by Stoddart Metal Bollards for Sidewalks by Stoddart

Metal Bollards for Sidewalks by Stoddart Metal Processing and Fabrication

Metal Processing and Fabrication Custom Shelters for Parks by Stoddart

Custom Shelters for Parks by Stoddart Mobile Wash Station by Stoddart

Mobile Wash Station by Stoddart Architectural Metalwork Bike Rack by

Architectural Metalwork Bike Rack by Commercial Kitchen Contracting Solutions

Commercial Kitchen Contracting Solutions Bike Parking Shelter by Stoddart

Bike Parking Shelter by Stoddart Vandal-Resistant Architectural Metalwork

Vandal-Resistant Architectural Metalwork Condensate Hoods for Kitchens from

Condensate Hoods for Kitchens from Restaurant Fire Suppression System for

Restaurant Fire Suppression System for