Correct Fitting of Respiratory Protection with 3M Respiratory Protection, it's not just about the mask. Ask anyone who has contracted a respiratory disease due to occupational hazards and they'll tell you it's scary. Chronic obstructive pulmonary disease, Silicosis, Mesothelioma, Pneumoconiosis and a host of others - it changes their lives, forever. Respiratory protection has come a long way since the ancient Romans used the bladders of goats and sheep to protect themselves from inhaling harmful asbestos fibres and lead dust in mines. However, even with all the technological innovations and regulations, the requirements for the correct use of respirators are not always met. In 2015, global deaths as a result of respiratory diseases made up 17% of the estimated 2.78 million occupational accidents and work-related fatalities based on the World Health Organization Regions. Even in this day and age, where the risks of workplace exposure to airborne contaminants are well documented, there are still several factors which discourage some workers from wearing their respiratory protective equipment, or from wearing it correctly. When asked why don't you wear your mask, some of the most common answers are:

If you don't think you need to wear a respirator, think again. You may not be able to see the hazards, but the danger is there, and its real. Even short periods of exposure to the contaminants in the workplace atmosphere could make you ill, or even worse, put you at risk of contracting a disease that is slow to develop but in many cases deadly. Whatever the excuse, it is not worth the risk to both your immediate or long term health. The laws of many countries mandate the use of appropriate control measures to provide a safe workplace, as part of this duty of care employers are required to keep exposure to airborne contaminants to a minimum by putting controls in place to eliminate the hazard. However, depending on the workplace and its environment, it is not always possible to eliminate the hazards, in these instances respiratory protection is required. In Australia and New Zealand, AS/NZS 1715 states that a respiratory protection program is required for workers to achieve a safe, reliable and ongoing level of protection from identified airborne contaminants. The standard also provides users with the information required to select and use appropriate respiratory protection products and highlights the requirement that all wearers of tight fitting masks be fit tested to prove that the selected mask can get an effective fit on the individual. Wearing a respirator that does not fit your face effectively puts you at risk of overexposure to potentially harmful airborne contaminants. Fit testing... the basics. If I wear a respirator, why do I need to be fit tested? Don't I just pinch the metal clasp at the nose and off I go? This is an all too common misconception and there is more to be taken into consideration than just pinching the nose clip. It's important to note that not all faces are created equally, we all have diverse shapes, sizes and facial features that need to be taken into consideration, as a result no manufacturer is able to produce a mask that fits all faces. The performance of tight-fitting facepieces depends on achieving a good contact between the wearer's skin and the face seal of the facepiece. This is where fit testing comes into play and ensures that the selected respirator actually fits the wearers face to ensure that the majority of contaminants are captured by the filter and do not slip through any gaps between the mask and the face. Examples of tight fitting respirators;

Fit testing, what is it? Respirator fit testing is a method for checking that a tight fitting facepiece, commonly known as a mask or respirator, matches the wearer's facial features and seals effectively to their face. If the seal is inadequate, contaminated air will take the path of least resistance and will travel through leaks in the face seal. The fit test also serves to ensure that incorrectly fitting facepieces are not selected for use, and that the wearer can don the respirator correctly to control exposure. The factors affecting fit. Faces vary in shape, size and proportion and it is unlikely that one particular model of respirator will fit everyone. Other factors affecting the seal of a respirator to a wearer's face include:

All wearers of tight fitting respiratory protective equipment should receive a fit test on the make(s) and model(s) of respirators that they are required to use. When should fit testing be conducted? Ideally, fit testing should be conducted during the initial selection stage, before a user wears the respirator in a hazardous environment. If an untested facepiece is already in use it should be fit tested as soon as possible. Fit testing should be repeated at regular intervals, it is good practice to repeat fit testing at appropriate time such as:

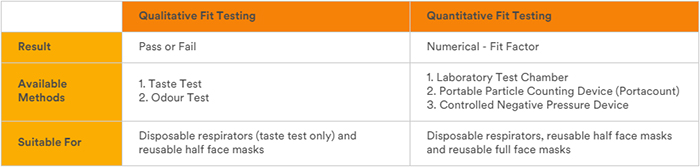

Who should conduct fit testing? Fit testing should be conducted by a competent person. To be considered competent, a person should have received adequate training and instruction, and should have appropriate knowledge and sufficient practical experience to conduct and interpret fit test results. If a worksite does not have an in-house competent person to conduct fit testing an occupational health nurse or occupational hygienist can be engaged. What methods of Fit Testing are available? When it comes to respiratory fit testing there are two basic types, qualitative and quantitative. During both methods of testing, it is essential that the subject is free from facial hair and other items that may interfere with the face seal. The table below provides a summary of each.

For more detailed information on each of the methods of fit testing refer to our Respirator Fit Testing Tech Update. Warning:

Breathe easy now, so you can breathe easy in years to come. Best practice for any Personal Protective Equipment is to ensure the right fit. A respirator can't protect you if it doesn't fit your face. Are you protected? Poor fit can have a negative impact on the respirator's overall filtering effectiveness and in turn negatively impact your health and well being, now and into the future. Proper fitting of a respirator requires the application of an accepted method of fit testing and it is recommended that wearers be fit tested in accordance with Australian/New Zealand Standard AS/NZS 1715:2009. Through science led innovation, 3M have been at the forefront of respiratory protection solutions. In 1969, 3M developed the first disposable face masks and were involved in the development, trial and authentication of qualitative fit testing protocols for respirators. Our Qualitative Fit Test Kits, FT-10 and FT-30, for the disposable and half-face reusable respirators fitted with particulate or combination gas/vapour and particulate filters offer a solution to prove an effective fit that meets the criteria of Australian and New Zealand standard 1715:2009. They also meets the fit testing criteria under OSHA Standard for Fit Testing Respirators: 29 CFR 1910.134, Appendix A. These kits are ideal for organisations with in-house resources to conduct qualitative fit testing.

Don't have an in-house resource? 3M can get you connected with an occupational health nurse, hygienist or fit test consultant to conduct qualitative or quantitative Fit Testing. Alternatively by working with 3M on a comprehensive respiratory programme we may include the provision of fit testing as part of the service offering. Register for Fit Testing. Contact a 3M Safety Specialist for more information or visit the 3M Centre for Respiratory Protection where you can explore step-by-step tools to ensure your respiratory protection is comprehensive and effective.

|

136 136 North Ryde, NSW, 2113

|

Edge Sealing for Graphic Film

Edge Sealing for Graphic Film Linesman Harness with D Ring by 3M

Linesman Harness with D Ring by 3M Entrance Mat for Industrial Facilities

Entrance Mat for Industrial Facilities Slip Resistant Mat for Wet Areas by 3M

Slip Resistant Mat for Wet Areas by 3M Advantages of Window Films for

Advantages of Window Films for Wet Look Finish for Terrazzo Floors by

Wet Look Finish for Terrazzo Floors by Compact Dust Extractor for Workshops by

Compact Dust Extractor for Workshops by Clear Lubricant for Wire Pulling by 3M

Clear Lubricant for Wire Pulling by 3M Matt Black Double Hook by 3M

Matt Black Double Hook by 3M Spray Protector for Fabric and

Spray Protector for Fabric and Under Sink Sponge Caddy by 3M

Under Sink Sponge Caddy by 3M Adhesive Mat for Clean Rooms by 3M

Adhesive Mat for Clean Rooms by 3M Heavy Duty Coarse Tape for Ships by 3M

Heavy Duty Coarse Tape for Ships by 3M Spray Bottle Hanger by 3M

Spray Bottle Hanger by 3M Hearing Protection Products by 3M

Hearing Protection Products by 3M All Season Window Film by 3M

All Season Window Film by 3M Black Out Privacy Monitor Screen by 3M

Black Out Privacy Monitor Screen by 3M Under Sink Water Filters for Kitchens by

Under Sink Water Filters for Kitchens by Sound Deadening Pads by 3M

Sound Deadening Pads by 3M Custom Head Protection by 3M

Custom Head Protection by 3M