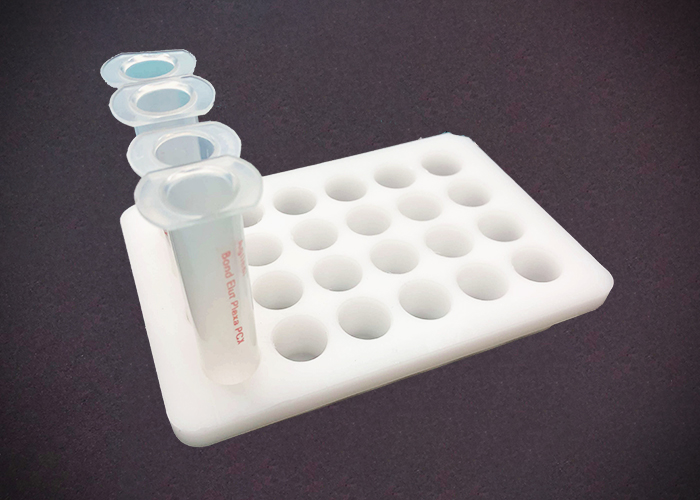

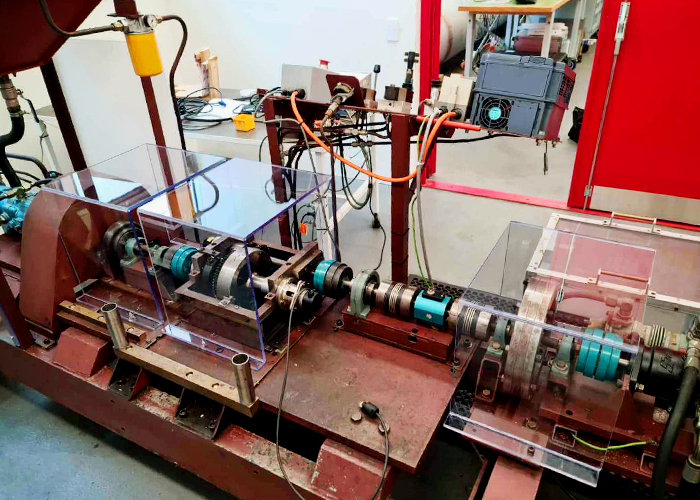

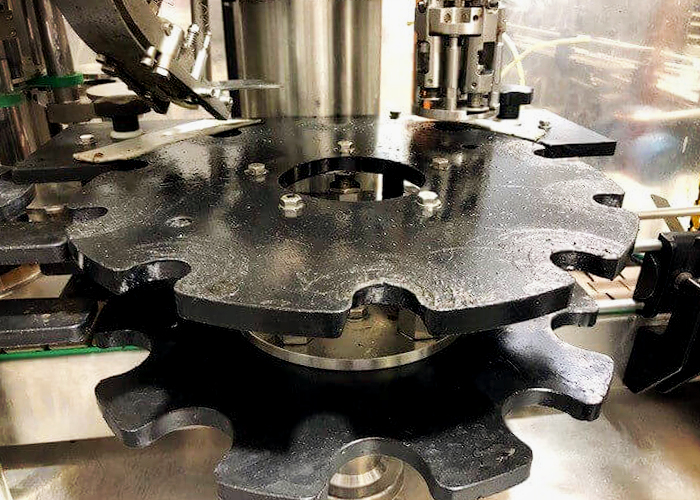

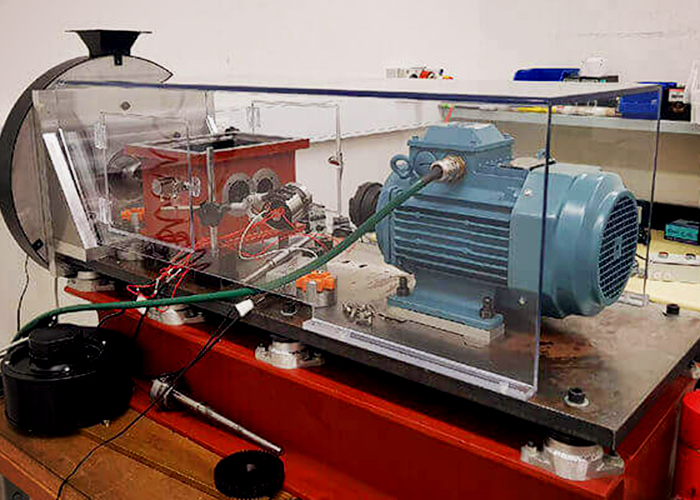

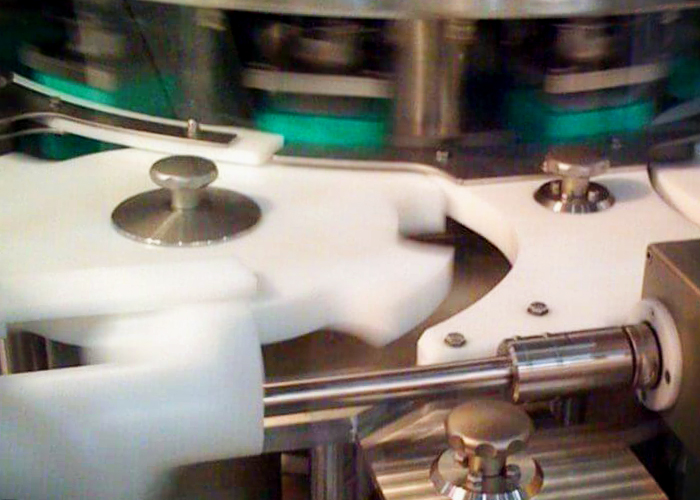

Engineered Plastics and the COVID-19 Vaccine with Allplastics Acrylic syringe holders. The COVID-19 Vaccine and Engineered Plastics Over the last 12 months the world has been dramatically changed as a consequence of the COVID-19 pandemic. The urgency of developing an effective vaccine has been a priority for many countries, health organisations, and pharmaceutical companies including Astra Zeneca, Pfizer, Moderna, and CSL. The packaging of pharmaceuticals in bottles/vials requires appropriate change parts such as star-wheels, scrolls, wear guides, conveyor curves, slats, rail protectors, and machine guards which allow the flow of the containers in the manufacturing line rapidly and safely. Allplastics Engineering has been providing custom machined wear parts for the packaging, food, and pharmaceutical industries for more than 40 years.  Machine guard. Some of the materials utilised in the industry include UHMWPE, high density polyethylene, Acetal, nylon and polycarbonate for machine guards. Allplastics Engineering specializes in the replacement of OEM (Original Equipment Manufacturer) parts for the packaging industry and can reverse engineer those plastic components to suit your specific requirements. Engineered plastic star wheels provide wear resistance, ease of machining, resistance to cleaners, oils, and greases. They are lighter in weight than metal star wheels and have a lower coefficient of friction. Plastic star wheels and wear parts are less likely to damage packaging or product as they promote the movements along the conveyor line. Let us play our part in overcoming the pandemic!

|

Allplastics Engineering Pty Ltd Profile 02 8038 2000 Unit 20, 380 Eastern Valley Way, Chatswood, NSW, 2067

|

Lightweight Stone Panel for Cladding by

Lightweight Stone Panel for Cladding by Bullet Resistant Polycarbonate Sheets

Bullet Resistant Polycarbonate Sheets Flute Board for Flooring Protection by

Flute Board for Flooring Protection by Fire Resistant Splashback for Kitchens

Fire Resistant Splashback for Kitchens Glass Mirror Alternative for Decorative

Glass Mirror Alternative for Decorative Stain-Resistant Surface for Benchtops by

Stain-Resistant Surface for Benchtops by Acrylic Noise Barriers by Allplastics

Acrylic Noise Barriers by Allplastics PVC Strip Curtains for Heat Loss

PVC Strip Curtains for Heat Loss Temperature Resistant Decorative Acrylic

Temperature Resistant Decorative Acrylic Object Encapsulation in Acrylic by

Object Encapsulation in Acrylic by High Gloss Acrylic Splashbacks by

High Gloss Acrylic Splashbacks by Polycarbonate Sheets for Cashier Windows

Polycarbonate Sheets for Cashier Windows Pastel Acrylic for Shops by Allplastics

Pastel Acrylic for Shops by Allplastics Outdoor UV-Resistant Glazing System from

Outdoor UV-Resistant Glazing System from Fire Retardant Splashbacks for Kitchens

Fire Retardant Splashbacks for Kitchens Zintra Acoustic Panels by Allplastics

Zintra Acoustic Panels by Allplastics Polycarbonate Glazing System for Roofs

Polycarbonate Glazing System for Roofs Stone Look Cladding Panel by Allplastics

Stone Look Cladding Panel by Allplastics Radiant Effect Acrylic Glass by

Radiant Effect Acrylic Glass by Anti Slip and Translucent Optic Flooring

Anti Slip and Translucent Optic Flooring