Swellseal Ultra, a Bentonite-based Membrane for Use in Seawater Applications by Neoferma SwellSeal ULTRA® was developed by Neoferma in order to satisfy the demand for a product that would function well under conditions of seawater contamination. As a result, the design characteristics for SwellSeal ULTRA® were for a product that, when exposed to pure sea water, would have a stable and long-lasting very low permeability to water movement.

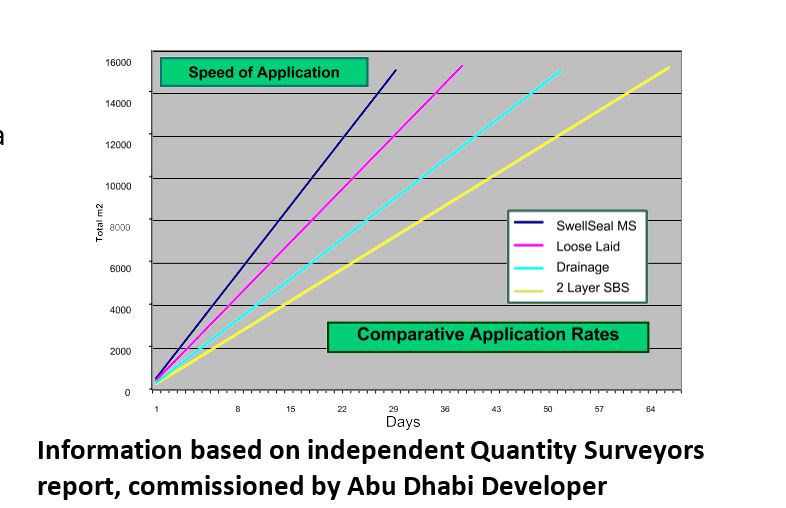

The capabilities of the SwellSeal ULTRA® bentonite mix have been demonstrated in extremely rigorous testing by independent engineering studies, such as those conducted by Mueser Rutledge Engineers of New York City, which qualified the bentonite mix for use on the Allied Signal Baltimore Works EPA Superfund Site project adjacent to the harbour in Baltimore, Maryland, which was required by the U.S. EPA to permanently contain the toxic and hazardous materials that had permeated the soil and groundwater at the site over its 200 years of industrial use. The bentonite component of SwellSeal ULTRA® was specified as being the only product that could be used for the permanent backfill that would enclose and contain the site. Why use SwellSeal Bentonite Membranes*?Independent surveys have found that using a Bentonite Membrane System in place of traditional waterproofing has significant advantages both in the speed of application and the beneficial effect on the construction programme, as well as savings in the overall cost of the waterproofing element.

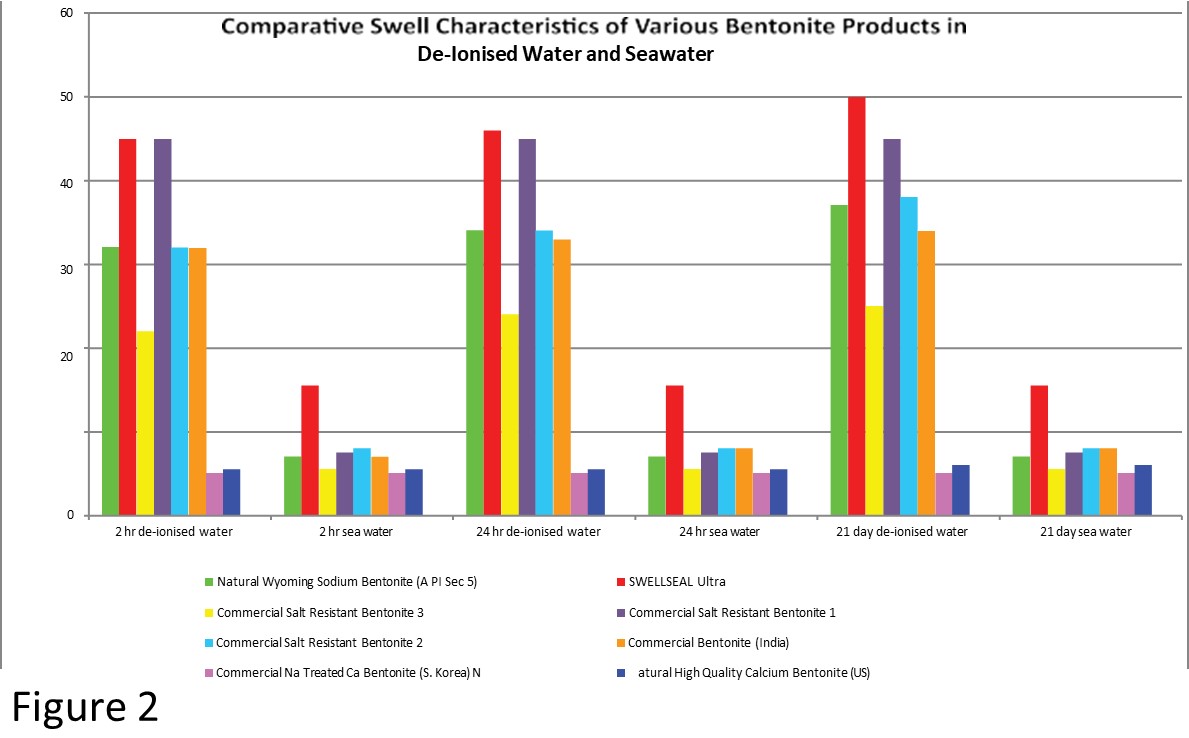

Does it work?Figure 2 illustrates the free swell characteristics of SwellSeal ULTRA® and several other bentonite products when measured in pure seawater. These results show that, while SwellSeal ULTRA® has a swelling capacity equal to or slightly higher than other bentonite products in fresh water, it has about twice the swelling capability of other bentonite products in seawater, including other supposedly salt-resistant products.

A better measure of the sealing capability of a bentonite product is through the measurement of its permeability (hydraulic conductivity) under controlled laboratory conditions. Permeability testing of a demonstration sample of a SwellSeal ULTRA® GCL (6.4mm thick layer of SwellSeal ULTRA® between layers of non-woven and woven geosynthetic fabric) together with samples of GCL products advertised as being seawater resistant was conducted by Geo- Syntech Laboratories of Alpharetta, Georgia, USA.

SwellSeal ULTRA® GCL yielded a permeability value

*The size of a roll of Ultra is: 7 .5 x 1.5 m, 4000 gms Mass of Bentonite per m2. Contact Neoferma today and find out how we can assist you: 1300 88 53 70 or neoferma.com Contact Neoferma today and find out how we can assist you: 1300 88 53 70 or neoferma.com

|

Neoferma Australia Pty Ltd Profile 07 5576 4922 West Burleigh, Qld, 4219 Shop Neoferma Australia Pty Ltd

|

Another Successful Waterproofing

Another Successful Waterproofing PUR-X® Blinder for Concrete-Free

PUR-X® Blinder for Concrete-Free Secondary Containment for Oil and Gas by

Secondary Containment for Oil and Gas by Concrete Blinding Replacement System for

Concrete Blinding Replacement System for Concrete Blinding Replacement System

Concrete Blinding Replacement System Neoferma Gasket Protecting the Facade of

Neoferma Gasket Protecting the Facade of Screen Injection for Deep Ventilation

Screen Injection for Deep Ventilation Concrete BLINDER Replacement System by

Concrete BLINDER Replacement System by Waterproofing Membrane for Below Grade

Waterproofing Membrane for Below Grade Secondary Containment for Oil and Gas by

Secondary Containment for Oil and Gas by Injection Materials from the PUR-X®

Injection Materials from the PUR-X® Dust Proofing Surface Sealant from

Dust Proofing Surface Sealant from Another Successful Waterproofing

Another Successful Waterproofing Flood Mitigation with the help of

Flood Mitigation with the help of Concrete BLINDER Replacement System by

Concrete BLINDER Replacement System by Neoferma Gasket Protecting the Facade of

Neoferma Gasket Protecting the Facade of Bentonite Membrane for Horizontal &

Bentonite Membrane for Horizontal & Dust Suppression for Construction Sites

Dust Suppression for Construction Sites Secondary Containment for Oil and Gas by

Secondary Containment for Oil and Gas by Dust Proofing Surface Sealant from

Dust Proofing Surface Sealant from