PTFE Component Machining from Allplastics Engineering PTFE (Teflon) is 80 Years Old! Did you know that one of the most commonly used polymers in recent decades was accidently discovered in 1938? PTFE (commonly known as Teflon) was a result of an attempt by Roy Plunkett, of the New Jersey laboratories of DuPont, to make a new chlorofluorocarbon refrigerant. During this process the tetrafluoraethylene gas in its pressure bottle stopped flowing before the bottle's weight had dropped to the point of signaling "empty." Plunkett was measuring the amount of gas by weighing the bottle and became curious as to the source of the weight. He finally resorted to sawing the bottle apart. The bottle's interior was coated with a waxy white material that was very slippery. Once analyzed it was shown to be perfluoroethylene. Kinetic Chemicals patented the new fluorinated plastic in 1941, and registered the Teflon trademark in 1945. By 1948, DuPont, which formed Kinetic Chemicals, in partnership with General Motors, was producing over 900 tons of Teflon brand PTFE per year.

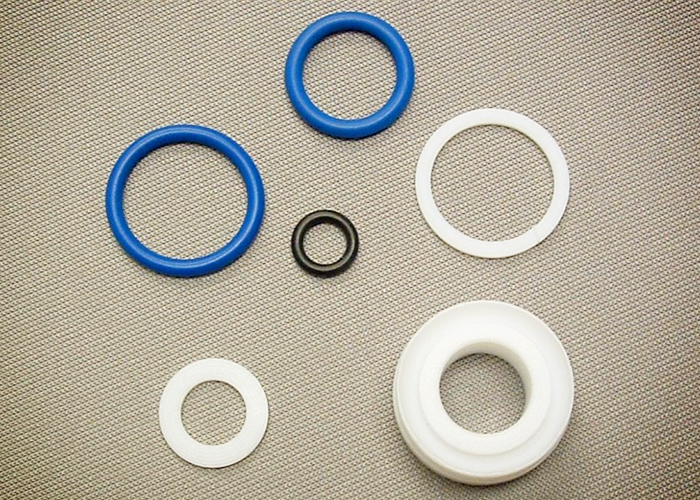

Over the next decade, Teflon was used as coating for non-stick cookware becoming a household name with patented brands such as Tefal and Happy Pan. Due to its excellent dielectric properties, especially at high radio frequencies, it was used as an insulator in connector assemblies and cables; and in printed circuit boards used at microwave frequencies. In industrial applications, owing to its low friction and high chemical resistance, PTFE is used for bushes, washers, gaskets, seals, slide plates, valve seats, tooling pins, and much more. Allplastics Engineering has been machining PTFE components over the last 44 years for a diverse range of industries including food, packaging, pharmaceutical, chemical, materials handling, and transport.

For special applications where virgin PTFE is not suitable, Allplastics can provide glass filled, carbon filled, and bronze filled PTFE. If the PTFE is required to be bonded to steel a chemically etched surface can be requested on one side of the sheet. Key Features

Applications

For more information regarding PTFE Component Machining from Allplastics Engineering, visit www.allplastics.com.au.

|

Allplastics Engineering Pty Ltd Profile 02 8038 2000 Unit 20, 380 Eastern Valley Way, Chatswood, NSW, 2067

|

Lightweight Stone Panel for Cladding by

Lightweight Stone Panel for Cladding by Bullet Resistant Polycarbonate Sheets

Bullet Resistant Polycarbonate Sheets Flute Board for Flooring Protection by

Flute Board for Flooring Protection by Fire Resistant Splashback for Kitchens

Fire Resistant Splashback for Kitchens Glass Mirror Alternative for Decorative

Glass Mirror Alternative for Decorative Stain-Resistant Surface for Benchtops by

Stain-Resistant Surface for Benchtops by Acrylic Noise Barriers by Allplastics

Acrylic Noise Barriers by Allplastics PVC Strip Curtains for Heat Loss

PVC Strip Curtains for Heat Loss Temperature Resistant Decorative Acrylic

Temperature Resistant Decorative Acrylic Object Encapsulation in Acrylic by

Object Encapsulation in Acrylic by High Gloss Acrylic Splashbacks by

High Gloss Acrylic Splashbacks by Polycarbonate Sheets for Cashier Windows

Polycarbonate Sheets for Cashier Windows Pastel Acrylic for Shops by Allplastics

Pastel Acrylic for Shops by Allplastics Outdoor UV-Resistant Glazing System from

Outdoor UV-Resistant Glazing System from Fire Retardant Splashbacks for Kitchens

Fire Retardant Splashbacks for Kitchens Zintra Acoustic Panels by Allplastics

Zintra Acoustic Panels by Allplastics Polycarbonate Glazing System for Roofs

Polycarbonate Glazing System for Roofs Stone Look Cladding Panel by Allplastics

Stone Look Cladding Panel by Allplastics Radiant Effect Acrylic Glass by

Radiant Effect Acrylic Glass by Anti Slip and Translucent Optic Flooring

Anti Slip and Translucent Optic Flooring