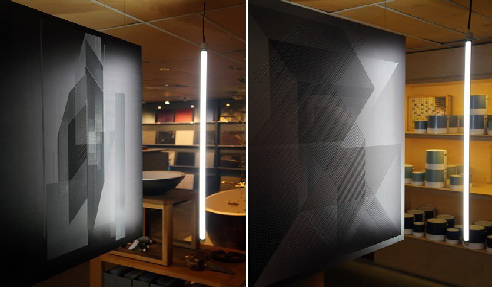

3D Printing Reborn with Architectural Art from Axolotl Axolotl introduced 3D printing in 2017, continuing its tradition as leaders in design innovation. Since then, it has partnered with architects and interior designers to create architectural artworks as well as originating exciting new products like Axolotl Terrazzo and Spectrum. We were excited to be featured recently in an article on new online magazine HouseLab, about Axolotl's capabilities in 3D printing. Print RebornWhen media became digitised the world screamed "print is dead" but, in fact, combining digital technology with age-old printing techniques has created an entirely new dimension to architectural surfaces that can be personalised across almost any application.  The 3D printed entry to Nina Maya Interiors' The Glasshouse (Photographed by Nicole England). Our connection with printed matter is more than coffee table books and the Sunday paper, it's like buying the LP when you can download the album on Spotify. It is the tangible, textured and large format. Take the bronze entryway to Nina Maya Interiors' recent project, The Glasshouse, in the Sydney suburb of Paddington - and yes, you'd be forgiven for thinking it took artisan hours, painstakingly etching the pattern. In fact, it is 3D printed and like a true artist's work it is completely a one-off - the skill of the modern digital artisan remains equally important as the traditional artist. That is the great thing about this new technology, combining the feel of the old with the potential of the new, and really the possibilities are endless when you combine an idea with those who know how to make it become reality. Making our way to the rear of The Glasshouse, this comes to light with a three-panel bronze cortex gate acting as a functional feature wall. Another example of how we can approach surfaces differently and the texture is as engaging as the finish. These new approaches to printing and surface treatments bookend the home and also showcase the possibilities we have to hand.  3D printed doors are just the beginning of what this new technology can offer. Left: Grand Designs by Chris Knierem - Design Construct (Photograph by Belinda Knierem). Right: Smith Residence in New Zealand by Di Smith (Photograph by Di Smith). The application of this technology isn't just limited to doors, nor is it limited to metal. Today we can print on virtually any substrate from terracotta to glass, including concrete and timber, with an added dimension of up to 150mm meaning it really does come down to your imagination. By engaging a graphic designer or artist in the process, any pattern can be achieved to create a statement piece in the home that is truly yours. HouseLab co-founder Marcus Piper recently pushed the boundaries of this thinking with his Differences series exhibited at the Australian Design Centre. Printing on aluminium plate, the graphically-geometric series showed how 2 and 3-dimensional printing can hang together as one - playing with light to create depth in what would otherwise be a flat plane. "It's like printing an enormous magazine cover and they look different from every angle!" says Piper, who has been designing magazines for the last 20 years and is now endlessly excited about the potential of being able to produce artworks up to 1600 x 2400mm. And really size is the only limitation here - be it a garage door, a contemporary take on a pressed-tin ceiling or a poolside glass facade it comes down to the mark you want to make, as combining these multiple printed panels opens up a world of opportunity. So, what lies ahead in surface technology? The sky is the limit but it ultimately comes down to finding the right team who understand the potential and can make the most of it in a way that suits a home. One thing is for sure, the print is well and truly alive and it is definitely going places.  Difference 03 and Difference 01 by Marcus Piper, printed and 3D printed on aluminium at the Axolotl showroom. The Take Homes

To find out more about the custom printing of architectural surfaces contact Axolotl.

|

02 9666 1207 Unit 6/73 Beauchamp Road, Matraville, NSW, 2036

|

Glass Bricks for Contemporary

Glass Bricks for Contemporary Custom 3D Design Front Doors by Axolotl

Custom 3D Design Front Doors by Axolotl Lustrous Paint for Indoor and Outdoor

Lustrous Paint for Indoor and Outdoor Concrete Balustrade for Staircases by

Concrete Balustrade for Staircases by Micaceous Water-Based Metallic Paint by

Micaceous Water-Based Metallic Paint by 3D Design on Natural Stone by Axolotl

3D Design on Natural Stone by Axolotl Sculptural Walls and Feature Panels by

Sculptural Walls and Feature Panels by Textured Glass Shower Screen by Axolotl

Textured Glass Shower Screen by Axolotl Custom Architectural Doors and Entrances

Custom Architectural Doors and Entrances Aged Sheet Metal by Axolotl

Aged Sheet Metal by Axolotl Veil Glass for Privacy by Axolotl

Veil Glass for Privacy by Axolotl Laminated Glass for Floors by Axolotl

Laminated Glass for Floors by Axolotl Bringing Nature to Modern Design by

Bringing Nature to Modern Design by Ripple Effect Stainless Steel by Axolotl

Ripple Effect Stainless Steel by Axolotl Custom Privacy Screens by Axolotl

Custom Privacy Screens by Axolotl 3D Embossed Doors by Axolotl

3D Embossed Doors by Axolotl Lustre Glass with Matt Blasted Satin

Lustre Glass with Matt Blasted Satin Custom Outdoor Planters by Axolotl

Custom Outdoor Planters by Axolotl Bronze 3D Designed and Printed Double

Bronze 3D Designed and Printed Double Custom Stained Glass for Modern Designs

Custom Stained Glass for Modern Designs