Polymers being plastics, are used for an array of applications from decorative to

industrial processes. This article reflects certified building and graded polymers and

coating applications.

With a number of polymer substrates in the market place which have a limited range

of colour ISPS Innovations provide an unlimited service on any colour, efx and digital

print on our Splashback and Wall Panel substrates. ISPS Innovations also offer any

colour on our doors and benchtops.

Bonethane® & IPA Acrylic™ come with GRIPTEK™ backing.

About Acrylic which submits relations to artificial, or synthetic, plastic textiles

containing one or more plagiaristic forms of acrylic acid. The most common acrylic

plastic is polymethyl methacrylate (PMMA), we may know the brand names better &

make associations around the world with names like PLEXIGLAS®, Lucite® &

Perspex® to name a few.

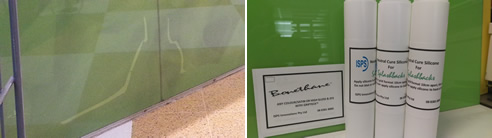

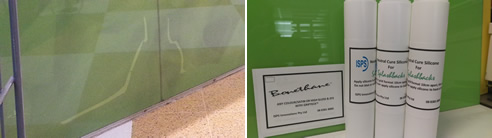

Check out this image the result of poor spraying application methods and chemical reactions.

How many times have you seen this is a shop front or home with a splashback or wall panel?

This happens after tricky coating warranties run out. With ISPS Innovations we create

innovative systems that deliver.

Poorly sprayed sheets resulting in bleeding silicone months after

install. Solution our silicone Innovative Formula

Quality Tested Silicone by ISPS Innovations

More about Polymers

PMMA (Acrylic polymer) is a hard wearing elevated crystal clear material which is

low heat bearing. Other grades like the thermal polymer brand Bonethane® is a high

heat bearing building graded polymer which is self extinguishing and may release a

light black/grey smoke when extinguished, just like a candle when the fire is put out.

The reason for this is that the product is designed to slowly ignite then

extinguish. Bonethane® is a Thermal Polymer: 7 year warranty doubled to 14 years when installed by our

method. Simple fast.

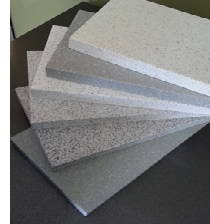

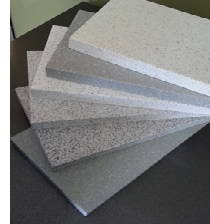

Image to the right, Bonethane® is 5th in the

line up (red sample).

Image to the right, Bonethane® is 5th in the

line up (red sample).

Products 2, 3, 4, 6 & 8

are Acrylic.

Products 1 & 7 are composite

panels under a candle burn test.

Bonethane VS Acrylic Splashback CandleBurn Test

The exceptional beauty of such Polymers,

dilutes the endless option of colour enhancement,

moulded, drilled, cut, planned & formed onsite prior

to placement.

ISPS Innovations want to discuss the interior choices

of acrylics(PMMA) & thermal polymer resins as

decorative splashbacks and wall panels, but first

lets discuss assembly.

The material qualities & types makes idyllic for numerous

functions including splashbacks, white

boards, projector screens, wall panels, air craft,

skylights, vehicle taillights, roofing, corporate or

commercial signs, your options are endless.

Take the polymer sheet assemble process:

Through the manufacturing process, storage & handling of polymers are

completed under managed environmental stipulations to avert corruption of the

material or risky chemical effects.

This is why it is imperative that the manufacturer or applicator of materials should be

questioned by the substrates origin if not already stipulated. Ensure that the

applicator who colour's your sheets have the experience and know how & able to

meet, standards, longevity of colour process from the bleeding silicone, delamination

which is attributed to water, heat and cold the list is endless.

ISPS Innovations are leaders in colour technology!

Take a look at our CulourTEK benchtops™ any colour

combination and non porous surface that look like stone. We

back our products with our own warranties and brand our

products we do not piggy back off of other leading brand

substrates to create a credible product. The director of ISPS

Innovations has 20 + years experience in the industry.

Temperature control of these polymers are especially critical in the

manufacturing process. In PMMA the release of the primary temperature of the

molecule (structure) are controlled before they are introduced to each other to cause

activity between the properties forming the polymerization for PMMA and other

critical processes for thermal polymer plastics, a vital system creating the polymer

sheeting. During the entire process, the temperature of the reacting material is

monitored & controlled to ensure the heating and cooling cycles are the appropriate

temperature &intervals follow succession development, creating the polymer sheet.

PLEXIGLAS® courtesy of EVONIK

Sections of the finished polymer substrates are

also given intermittent laboratory examination

to substantiate material objective and that the

optical and chemical reaction sustains the

purpose of its outcome.

This means that under a controlled

environment the constitution of the sheet is

viable to the elements described in the data

sheet for commercial or domestic application,

not the process of which it is formed under

which is a controlled laboratory environment.

So when "flyby applicators apply colour coating" to the back of a polymer substrate... the original MSDS,

material safety data sheet supplied by the original manufacturer can be void.

ISPS have strict mandatory installation steps which cover you. We provide detailed install process that

must strictly be followed. Other companies piggy back of the manufactures warranties applying their

coating & giving no accreditation for their own warranties works.

ISPS Innovations supply

ISPS Innovations supply

- Acrylic Polymer Sheeting (PMMA) an amazing durable substrate.

- Fused Acrylic sheeting with colour bonded and designed to run through the

course of the sheet which is priced to please and in selected colours.

PLEXIGLAS Hi Gloss®

- Bonethane® Premium Sheeting a high heat thermal polymer available in any

colour.

- Benchtops in CulourTEK, available in any colour.

- Kitchens

- Brick Rejuvenation application

- VetroPoly Glass

- Satin Etched Glass

- Digital Printed Splashbacks

- Kitchen & benchtop resurfacing

- If you can envision it, ISPS Innovations will make it!

Please take note of our logos

ISPS Innovations have a range that is specialized and aimed to please.

In this image from the right is Acrylic,

Bonethane® and Glass

IPA Acrylic™, Bonethane®, Glass all look the

same but perform differently.

Our IPA Acrylic Splashbacks and Wall panels are an amazing substrate in the right

environment, durable & the clarity is unsurpassed. In the wrong environment it is

highly flammable. Acrylic in a fire amongst clean air will continue to burn sucking the

life out of your oxygen and spreading flames to other building materials.

Glass is a beautiful substrate it has in limitations

just like all substrates. Lets not forget, toughened

glass not only looks great but serves a specific

purpose behind Gas Hobs amongst other wonderful

attributes.

Glass is a beautiful substrate it has in limitations

just like all substrates. Lets not forget, toughened

glass not only looks great but serves a specific

purpose behind Gas Hobs amongst other wonderful

attributes.

See this silver glass image, after having this panel

on a wall for two years our client woke to a loud

noise and found a devastating surprise.

Our first question when looking. Did something impact the glass? From the front it

appears so but if you look at the impact centred it's behind the glass not in-front.

Now glass doesn't just explode..... Which takes us to the placement of the glass and

it's fit and or surrounding impact zones.

Correct processes and allowances require thought and deliberation before you

choose or apply your splashback choice. With glass a qualified manufacture and

fitter can eliminate any headaches.

Bonethane a high heat polymer that is suitable for indoors and outdoors UV treated

and comes with a 14 year warranty in a few easy steps. No splitting or cracking,

simple fast and an affordable luxury for the DIY devotee's. NOTE no polymer

substrate is suitable behind a gas burner.

Coatings: When a coloured coating is applied to the back of a polymer sheet or

glass this can change the constitution & integrity of the substrates, reflecting the

purpose of use. Quality testing of coating against reactions of heat expansion,

contraction, delamination or worse combustion, should be addressed. Coatings on

the backs of sheets release vapours in the event of a fire or extreme heat.

Don't think sprayed glass is any safer, the glass can cope with heat greater than the

coating on the back of the glass & that is a fact. So before you read any ridiculous

comments from "applicators" that piggy back off of industry leading products with

proven performance on the polymer substrate ask your self will the actual

manufacture of the sheet warranty it once coloured or are you buying a quality

substrate with unconventional application processes and false promises in the wrong

environment which your lead to believe works.

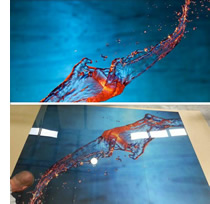

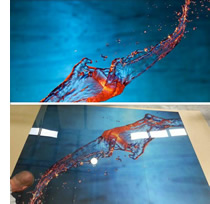

Take a look at this gorgeous cafe in Sydney we did with our IPA Acrylic™ sheets, specified by

an Architectural firm. Our client required 2m x 3m sheets and the sheets were applied with

GRIPTEK™ backing and encased all around the shops internal space. Below.

ISPS Innovation Splashbacks in Bonethane,

IPA Acrylic™ and VetroPoly™ Toughened glass are

Australian made & carry the certified logo Visit Australian Made

ISPS Innovation Splashbacks in Bonethane,

IPA Acrylic™ and VetroPoly™ Toughened glass are

Australian made & carry the certified logo Visit Australian Made

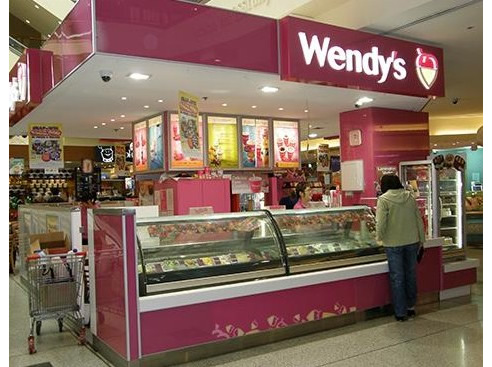

ISPS Innovations have supplied Bonethane®, IPA Acrylic™ Splashbacks and

VetroPolyGlass™ to hardware chains all over Australia for many years. With clients

like Bunnings, Mitre10, Anz Bank, Wendys, Priceline to name a few and appearing

on Chanel 10's The Renovator, Better Homes and Gardens & featured with the

Womans Weekly stand at the Easter show clearly showcases our services and

Innovation which is unique to the industry, so without further delay.....

ISPS Innovations announce we have a new online shop. If you require the

right information and an abundance splashback, wall panels and building material

choices delivered to your door call ISPS Innovations, we have something for

everyone in any colour, colour combination, digital print & cut to size.

Wendy's in Sydney

www.ispsinnovations.com.au

ISPS Innovations Face Book Page

Bonethane Facebook Page

Have a creative day with ISPS Innovations™

© November 2015 written by Theresa Leonardos

Some of these images are:

PLEXIGLAS® Range courtesy of Evonik

Bonethane Splashbacks ®

CulourTEK Benchtops ™

Polymer & Acrylic Splashback online shop

Please refer to cookies policy on our

website http://www.ispsinnovations.com.au/warranty-guidelines.html

Image to the right, Bonethane® is 5th in the

line up (red sample).

Image to the right, Bonethane® is 5th in the

line up (red sample).

ISPS Innovations supply

ISPS Innovations supply

Glass is a beautiful substrate it has in limitations

just like all substrates. Lets not forget, toughened

glass not only looks great but serves a specific

purpose behind Gas Hobs amongst other wonderful

attributes.

Glass is a beautiful substrate it has in limitations

just like all substrates. Lets not forget, toughened

glass not only looks great but serves a specific

purpose behind Gas Hobs amongst other wonderful

attributes.

ISPS Innovation Splashbacks in Bonethane,

IPA Acrylic™ and VetroPoly™ Toughened glass are

Australian made & carry the certified logo

ISPS Innovation Splashbacks in Bonethane,

IPA Acrylic™ and VetroPoly™ Toughened glass are

Australian made & carry the certified logo

Custom Splashbacks for Commercial

Custom Splashbacks for Commercial From Artwork to Splashback by ISPS

From Artwork to Splashback by ISPS Custom Laundry Rooms for Homes by ISPS

Custom Laundry Rooms for Homes by ISPS Printed vs Plain Splashbacks for

Printed vs Plain Splashbacks for DIY Friendly Splashback for Kitchens by

DIY Friendly Splashback for Kitchens by Care and Maintenance for CulourTek

Care and Maintenance for CulourTek Kitchen Cabinetry Update by ISPS

Kitchen Cabinetry Update by ISPS Bespoke Kitchen Splashbacks for Homes by

Bespoke Kitchen Splashbacks for Homes by Splashback for Home Entertainment Bar

Splashback for Home Entertainment Bar Benefits of Acrylic Splashbacks for

Benefits of Acrylic Splashbacks for Custom Black and White Printed

Custom Black and White Printed Advantages of CulourTek Countertops by

Advantages of CulourTek Countertops by Acrylic Markerboard for Schools by ISPS

Acrylic Markerboard for Schools by ISPS IPA Acrylic for Laundry Rooms by ISPS

IPA Acrylic for Laundry Rooms by ISPS Custom Kitchen Remodelling by ISPS

Custom Kitchen Remodelling by ISPS Custom Splashback for Kitchens from ISPS

Custom Splashback for Kitchens from ISPS Self Extinguishing Kitchen Splashback by

Self Extinguishing Kitchen Splashback by Resurfacing and Restoring Kitchens by

Resurfacing and Restoring Kitchens by CulourTek Benchtops by ISPS Innovations

CulourTek Benchtops by ISPS Innovations DIY Coloured & Printed IPA Acrylic

DIY Coloured & Printed IPA Acrylic