Tile Installation Systems for Sydney Aquatic Centre by LATICRETE Sydney Aquatic Centre Project

LOCATION: Sydney Aquatic Centre, Olympic Park Homebush Bay, NSW, Australia 12 Years on and Still Good as New - Sydney Aquatic Centre, Leisure Centre at Olympic Park Homebush Bay, NSW. When we say LATICRETE provides proven installation systems for tile and stone application, we mean it, 110%. For example, some of the world renown projects which have LATICRETE installed "all over them" are: The Petronas Tower - Malaysia, Burj Al Arab - Dubai, Sears Tower - Chicago USA and focusing closer to home, The National Library - Canberra, Flinders Street Railway Station - Melbourne and The Sydney Aquatic Centre at Olympic Park...just to name a few. After 12 years, The Sydney Aquatic Centre Leisure Centre still looks good as new. This project was completed in 2002.

Rendering and Screeding - LATICRETE 226 Thick Bed Mortar was gauged with 3701 Mortar Admix to produce a high strength and chemical resistant mortar. A mechanical mixer was used to ensure the large quantities of LATICRETE 226 Thick Bed Mortar/3701 Mortar Admix used was correctly and economically mixed to right consistency. For every bag of LATICRETE 226 Thick Bed Mortar that was put into the mixer, 1.9 to 2.3 litres of LATICRETE 3701 Latex Admix was added. The different quantities of 3701 latex is used to produce a wet wall render or a semi-dry floor screed depending on the application. The LATICRETE render mix was applied to the vertical surfaces, struck off and finished in a manner very similar to normal renders. Prior to the application of the floor screeds, a bond coat was used. LATICRETE 4237 Latex Additive and 211 Crete Filler Powder was combined in a bucket and mixed to produce a toothpaste consistency type mix which is then broomed/trowelled onto the floor just prior to the application of the semi-dry screed mix. The screed mix was then compacted and floated to a wood float finish. LATICRETE latex mortar toppings and renders bond monolithically to the concrete surfaces and is an excellent surface background for the following waterproof coat. (See Photograph 2.)

Waterproofing Membrane - LATICRETE 9235 Waterproofing Membrane was applied to the dimensionally corrected shell. This liquid applied, fabric reinforced, load bearing membrane is designed to be tiled directly to. Application is made by applying a liberal coat of the liquid, of a manageable size onto the wall or floor. A precut piece of fabric is then laid over the top of the first coat and broomed or brushed to work the liquid from beneath, to the top face of the fabric. When fabric saturation has been achieved a top coat is rolled over the top. When this has dried, a final coat is applied. The corners and coves have a two ply application and all fabric is lapped a minimum of 50 mm. Typically the detail work is done first with the remainder of the body work after. After the waterproof is complete it is allowed to cure for 7 days before the flood testing is done. (See Photograph 3.) Tiling - The very thin 20x20 vitrified mosaics on this project were fixed directly to the waterproof membrane with LATICRETE 4237 Latex Additive and LATICRETE 211 Crete Filler Powder. The adhesive was notched using a small V trowel. Once the tiles were placed on the adhesive, they were beaten in with the flat face of the trowel to ensure full bedding. Tiles were removed periodically to ensure sufficient adhesive was being used to maintain the full bedding. The LATICRETE 4237 Latex Additive/211 Crete Filler Powder provides a permanent bond to the LATICRETE 9235 Waterproofing Membrane that can sustain submersion for the life cycle of the project.

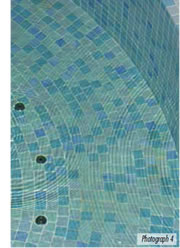

It was applied to the joints and excess removed with a rubber float. Final cleaning of the tiles was accomplished with wet towels and pads. This grout is also vertical grade which allows wall application without slumping. LATAPOXY SP-100 is the obvious choice where chemical resistance is required under almost all immersed conditions. (See Photograph 4.) When we say we provide Proven Installation Systems for Tile and Stone Applications - we do! For more information about LATICRETE, call 1800 331 012 or go to www.laticrete.com.au

|

1800 331 012 29 Telford Street, Virginia, Qld, 4014

|

Substrate Preparation - LATICRETE were involved

right from the start when the original tiling was

demolished and the remaining renders and

screeds were deemed not suitable. LATICRETE

3701 Mortar Admix/226 Thick Bed Mortar was

used for the new structural toppings and beds. The

existing renders and screeds were mechanically

removed and the surface was then grit blasted to

provide an open pored, sound and clean concrete

surface for the levelling screeds and renders.

(See Photograph 1.)

Substrate Preparation - LATICRETE were involved

right from the start when the original tiling was

demolished and the remaining renders and

screeds were deemed not suitable. LATICRETE

3701 Mortar Admix/226 Thick Bed Mortar was

used for the new structural toppings and beds. The

existing renders and screeds were mechanically

removed and the surface was then grit blasted to

provide an open pored, sound and clean concrete

surface for the levelling screeds and renders.

(See Photograph 1.)

Grouting - After the tiles were laid and cleaned

up, LATAPOXY® SP-100 Stainless Epoxy Grout

was placed into the joints. The mosaic tiler

easily applied and cleaned off the grout, leaving

a spectacular finish. The grout comes in 3 parts

and after the Part A & B are mixed, the Part C

powder is added to achieve the right consistency.

Grouting - After the tiles were laid and cleaned

up, LATAPOXY® SP-100 Stainless Epoxy Grout

was placed into the joints. The mosaic tiler

easily applied and cleaned off the grout, leaving

a spectacular finish. The grout comes in 3 parts

and after the Part A & B are mixed, the Part C

powder is added to achieve the right consistency.

Water-Based Primer for Waterproofing

Water-Based Primer for Waterproofing Self-Curing Waterproofing Membrane for

Self-Curing Waterproofing Membrane for Mortar for Stone Wall Cladding by

Mortar for Stone Wall Cladding by Adhesive Mortar for Tile Protection by

Adhesive Mortar for Tile Protection by Oil Stain Remover for Natural Stone by

Oil Stain Remover for Natural Stone by Advantages of Single Source Systems for

Advantages of Single Source Systems for Grout for Wide Joints by Laticrete

Grout for Wide Joints by Laticrete Uncoupling Mat for Tile Installations by

Uncoupling Mat for Tile Installations by Moisture Shield Epoxy Coating by

Moisture Shield Epoxy Coating by Sound Isolation Protection for Tiles by

Sound Isolation Protection for Tiles by Stain Protection for Natural Stones by

Stain Protection for Natural Stones by Polymer Fortified Mortar for Masonry

Polymer Fortified Mortar for Masonry Soap Scum Remover for Natural Stone by

Soap Scum Remover for Natural Stone by Acoustical Underlayment by Laticrete

Acoustical Underlayment by Laticrete No Seal Cement Grout by Laticrete

No Seal Cement Grout by Laticrete Cement-Based Capping for Interior

Cement-Based Capping for Interior Epoxy Adhesive for Tiles from Laticrete

Epoxy Adhesive for Tiles from Laticrete Salt Water Resistant Sealer from

Salt Water Resistant Sealer from Hydro Ban Slurry for Pools by Laticrete

Hydro Ban Slurry for Pools by Laticrete