Lintels & Galintels Sydney from Vincent Buda 180mm Cavi T Bar Galintel Cavi-T-Bar™ Lintel

The Galintel Cavi-T-Bar™ lintel is the ideal solution for cavity walls, either double brick, or brick veneer with timber trusses. The Cavi-T-Bar™ was developed in response to demand from builders for an economical substitute for built-up steel sections such as parallel flange channel and plate. Similar to a T-bar but with a special top flange incorporated into the upright section, the Galintel Cavi-T-Bar™ provides an off-the shelf solution for cavity walls, hot-dip galvanised, fully engineered and university tested. Available from accredited Galintel® distributors, the Cavi-T-Bar™ is a convenient alternative to custom-made lintels such as PFC and flat plate beams, which have to be fabricated and galvanised. As with all quality Galintel® products, the Cavi-T-Bar™ lintel is provided with a full product warranty and safe load tables. The Galintel® brand is your guarantee of quality, performance and code compliance. The quick, economical solution for cavity walls:

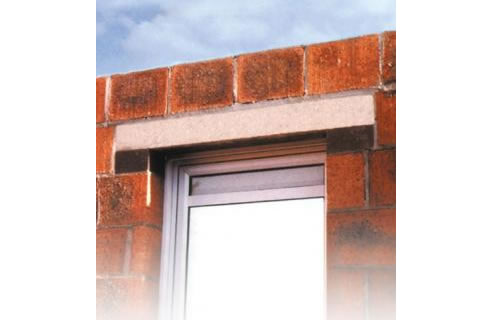

PGH Lintels

Concrete Lintels

A range of purposely designed Ultrafloor Lintels is also available for use with the suspended flooring system or wherever else necessary. Ultrafloor Lintels are:

Construction Notes Composite Action The load carrying capacity of the Ultrafloor lintels increases significantly when they act compositely with the brickwork above. This additional strength depends on the number of brick courses applied and the tables provided in this brochure give an indication of the maximum spans in different configurations. The following instructions are important:

Bearing Length

|

02 9740 1500 82 - 88 Benaroon Road, Belmore, NSW, 2192

|

Lintel Bars in Various Lengths | Vincent

Lintel Bars in Various Lengths | Vincent Light Weight Lintel Render Bar | Vincent

Light Weight Lintel Render Bar | Vincent Complete Range of Lintels Available |

Complete Range of Lintels Available | Budabar Steel Lintels, Vincent Buda

Budabar Steel Lintels, Vincent Buda Galintel Cavi T Bar, Vincent Buda &

Galintel Cavi T Bar, Vincent Buda & Galintel Products and Video from Vincent

Galintel Products and Video from Vincent