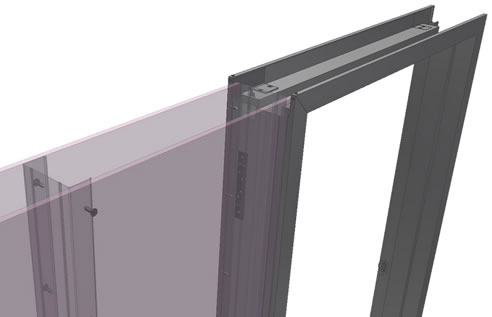

Weld Free Door Frame from Taylors Doors and Frames Taylors Weld Free Frame Anecdotal evidence suggests that 90% of welded door frames start to show signs of corrosion within only 6 months of installation. A major contributing factor in this is the process of welding which destroys the raw materials protective coating. Taylors advanced manufacturing process utilises a structurally proven cold formed metal self-piercing rivet (SPR) joining system ( a joining system used extensively in aircraft fuselage joining and long-haul heavy truck chassis manufacture). By using this it avoids degrading the raw material base coating with heat, weld perforation and surface grinding. It is not only the join strength and integrity of the raw material coating that should make a Taylors Weld Free Frame your first choice in design, building and construction but the fact it is supported by TDF five (5) year warranty.

|

Taylors Doors and Frames Profile 02 9905 1222 20 Orchard Road, Brookvale, NSW, 2100

|

Stainless Steel and Zinc Plated Hinges

Stainless Steel and Zinc Plated Hinges Stainless Steel Clad Fire Doors by

Stainless Steel Clad Fire Doors by Pressed Metal Door Frames Sydney by

Pressed Metal Door Frames Sydney by Door Frame & Door Kits from Taylors

Door Frame & Door Kits from Taylors Fire Resistant Commercial Doors from

Fire Resistant Commercial Doors from Pressed Metal Door Frames Sydney from

Pressed Metal Door Frames Sydney from Purchasing Door Frames | Taylors Doors

Purchasing Door Frames | Taylors Doors Pressed Metal Door Frames | Taylors

Pressed Metal Door Frames | Taylors Reducing Door Frame Corrosion | Taylors

Reducing Door Frame Corrosion | Taylors Controlling Door Frame Corrosion |

Controlling Door Frame Corrosion | Fire Door Reinforcing Plates | Taylors

Fire Door Reinforcing Plates | Taylors Frame Fixing for Masonry Walls | Taylors

Frame Fixing for Masonry Walls | Taylors Slider Frames for Stud Walls | Taylors

Slider Frames for Stud Walls | Taylors Fire Rated Frame Fixings, Taylors Doors

Fire Rated Frame Fixings, Taylors Doors Fire Rated Doors, Taylors Doors &

Fire Rated Doors, Taylors Doors & Door Frame Fixings, Taylors Doors &

Door Frame Fixings, Taylors Doors & Masonry Frame Fixing, Taylors Doors

Masonry Frame Fixing, Taylors Doors Dry Wall Frame Fixing, Taylors Doors

Dry Wall Frame Fixing, Taylors Doors Metal Door Joining System, Taylors Doors

Metal Door Joining System, Taylors Doors Architectural Metal Door Frames, Taylors

Architectural Metal Door Frames, Taylors