How much of the tile joint needs to be filled with grout? Is it right to just fill any remaining space left in the grout joints after the tile laying process is complete? What if I am relying on stress absorbing grouts in the joints? Do you need to grout at all? What are the key considerations when the grout chemistry is different to the adhesive chemistry?

I get these types of question on a fairly regular basis. I hope the following observations will provide some clarification.

I recently found myself in the middle of a robust discussion on how much space should the grout actually occupy in the joint and to what extent should the adhesive be removed from the joint during or after the fixing process.

In this case, the grout was epoxy and the adhesive material was cementitious. The contractor objected to the engineer's assertions and his specification that the joints should be completely filled with epoxy grout and that the tile laying operation should be carried out in such a way to achieve this objective.

Firstly, I pointed out that if the engineer specified this, he had the right to enforce it. Next, I went straight to our tiling guide AS3958.1 & 2 to see what it had to say and whether there was any guidance on this matter that was in line with, or contrary to, what I thought.

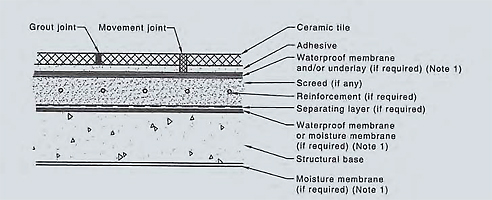

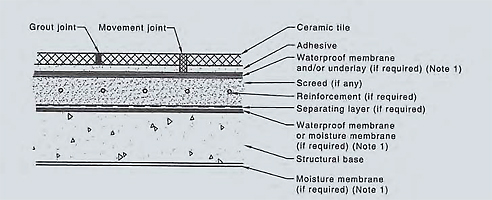

Figure 1.1.

The information on grouting in the tiling guide, amongst other things, includes a definition of adhesive, grouting/grout and a diagram of a tile joint, (Figure 1.1*). - This is the only illustration of a filled tile joint in the guide.

Recommendations regarding joint widths and alignment are accompanied by advice about the removal of any surplus bedding materials and removal of tile spacer pegs, prior to grouting. Advice is also given about removal of building dust and deleterious material prior to grouting.

While I agree with this advice I did not find any precise or definitive information and discussion on whether a joint was required to be totally filled from top to bottom of the tile with the specified grout.

So, am I to assume from the featured image and the advice provided in regard to removal of surplus bedding material, that these are a requirement for achieving a totally filled joint - unless, of course, the bedding material and grout are one and the same?

The guide goes on to advise that higher strength grout mixes may not take up induced stresses as well as lower strength mixes. Would this also mean that high strength adhesives would need to be removed from the joint prior to installing stress absorbing or compressible grouts? My answer is yes to all, but with some caveats.

For instance, I see no real need to remove a sound, improved cementitious adhesive layer from the lower parts of say a 10mm deep joint where a CG2 grout is specified and adequate movement joints are in place. However, I would have a problem where varying depths of adhesive resulted in grout thicknesses that range from say 2 - 8mm in the joint, which amongst other things, may create inconsistent curing and colour variation issues. This is also relevant where, contrary to good trade practice, plastic spacer pegs are left in the joints creating varying grout thicknesses.

On the other hand, if the intention was to use a stress forgiving grout I would definitely advocate that the grout should be installed to the full joint depth unless the bedding mortar or adhesive was of the same compressive strength and general characteristics.

However, where grout is to be used with a thin tile, say around 3mm thick, in consistently thin layers, or as skims greater than 1.5mm thick, it is important that the grout is installed to its designed thickness. The structural integrity of the background and the ability of the grout to bond to these backgrounds and the tile flanks will maintain its durability and aesthetics.

In immersed conditions and in areas subject to heavy wear, it is critical that the prepared backgrounds are sound and stable. Projects of this kind require a suitably experienced tile fixer to ensure that the grout is applied evenly to the required depth and that joints are finished flush and smooth.

The cleaning off process is critical, especially where epoxy grouts are employed. Poor installation practices have a tendency to leave shallow, washed-out, concave and under filled grout joints that result in typically thinner than desirable sections that become problematic and obvious, especially where the grout colour varies from the adhesive colour. So the deeper and more even in thickness the joints can be made the better it will be for the grout aesthetics, curing and durability.

Epoxy grouts are used for their greater chemical resistance, durability and aesthetic qualities. When an epoxy grout is to be applied to a tile laid with a cementitious adhesive, it would make sense to provide sufficient depth to allow the grout to perform as expected. Joints must be cleaned out to allow for the full designed grout thickness otherwise the purpose of using epoxy grouts may be defeated.

Cementitious grouts can fail to bond to the dense often glassy surfaces of an epoxy adhesive. This may be especially problematic when thin tiles are specified. Static/dynamic physical loads and chemical softening caused by chemical imbalances in pool water will exacerbate or accelerate likely problems with shallow installations of cement grouts. I would maintain that epoxy grouts should be used, especially when shallow grout joints are used in association with slim tiles. Coloured epoxy adhesives with matching coloured grouts are available and would help greatly in this situation.

One of my major objections to not grouting stone or tile work relates to efflorescence, which may occur in exposed installations, or in situations where tiles are constantly immersed or are subjected to constant wetting. For example, exposing open jointed tile or stone work to the cyclic effects of water flow over an infinity edge spill wall will nearly always result in disfiguring efflorescence.

I believe that when and wherever possible it is always good practice to fully grout all work.

* Figure 1.1 from AS3958.1-2007 - the only diagram in the guide depicts a fully filled grout joint.

Water-Based Primer for Waterproofing

Water-Based Primer for Waterproofing Self-Curing Waterproofing Membrane for

Self-Curing Waterproofing Membrane for Mortar for Stone Wall Cladding by

Mortar for Stone Wall Cladding by Adhesive Mortar for Tile Protection by

Adhesive Mortar for Tile Protection by Oil Stain Remover for Natural Stone by

Oil Stain Remover for Natural Stone by Advantages of Single Source Systems for

Advantages of Single Source Systems for Grout for Wide Joints by Laticrete

Grout for Wide Joints by Laticrete Uncoupling Mat for Tile Installations by

Uncoupling Mat for Tile Installations by Moisture Shield Epoxy Coating by

Moisture Shield Epoxy Coating by Sound Isolation Protection for Tiles by

Sound Isolation Protection for Tiles by Stain Protection for Natural Stones by

Stain Protection for Natural Stones by Polymer Fortified Mortar for Masonry

Polymer Fortified Mortar for Masonry Soap Scum Remover for Natural Stone by

Soap Scum Remover for Natural Stone by Acoustical Underlayment by Laticrete

Acoustical Underlayment by Laticrete No Seal Cement Grout by Laticrete

No Seal Cement Grout by Laticrete Cement-Based Capping for Interior

Cement-Based Capping for Interior Epoxy Adhesive for Tiles from Laticrete

Epoxy Adhesive for Tiles from Laticrete Salt Water Resistant Sealer from

Salt Water Resistant Sealer from Hydro Ban Slurry for Pools by Laticrete

Hydro Ban Slurry for Pools by Laticrete