Efficient Centrifugal Water Filtration for Cooling Towers by Waterco Waterco's MultiCyclone increases cooling tower efficiency while reducing downtime Particulates entering cooling tower systems are the bane of many a plant, causing unnecessary downtime and spiralling costs. During process cooling, the cooling water absorbs large volumes of airborne particulate while the cooling tower acts as an air scrubber, filtering the surrounding air. With time, these fine particles can build up and settle within the system, significantly reducing cooling performance. One of the ongoing challenges faced by industrial cooling water programs is how to remove these particles efficiently while minimising water and energy consumption. In addition to corrosion, an accumulation of particles contributes to the following challenges:

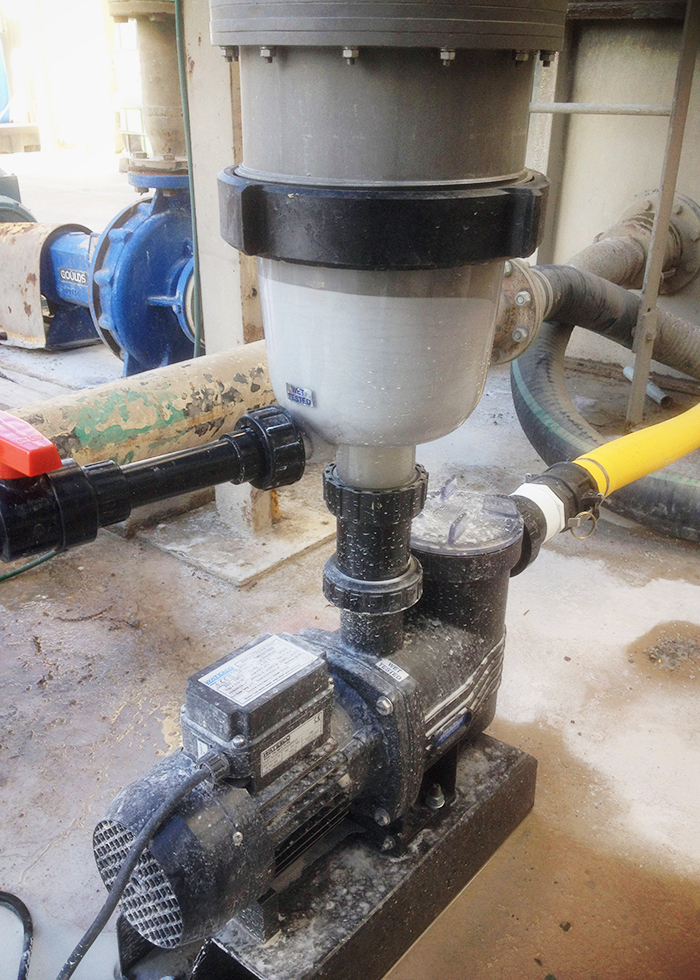

Accumulated particles from the cooling tower resemble concrete blocks. Paul Koutoufides, a respected water treatment specialist from Edge Complete Water Management Solutions, turned to Waterco to ensure his client's cooling towers were operating at optimum levels. "We needed a system that was easy to use and could withstand contact with harsh chemicals." The solution? Waterco's award-winning MultiCyclone 16 Centrifugal Filter.  Waterco's MultiCyclone is full of sediment after just eight hours of operation. Centrifugal Water Filtration: How It Works Designed with no moving parts that wear down nor filter media to clean or replace, this dual-filtration device pre-filters up to 80 per cent of the filter's incoming dirt load - easing the workload of the main cartridge filter. "As MultiCyclone intercepts more and more dirt, the flow rate remains unchanged," explains Lonny Ware, Waterco's Commercial and Water Treatment Sales Executive. Also known as centrifugation, centrifugal filtration is a highly accelerated form of sedimentation used to separate or concentrate materials suspended in a liquid medium. Here's a snapshot of how MultiCyclone works:

"Cleaning MultiCyclone is as simple as opening the purge valve," says Ware. "And you only lose 15 litres of water during the entire process."  Untreated water compared with water filtered through MultiCyclone. Cost and Labour Benefits When companies like Edge Complete Water Management Solutions stake their reputation on delivering high quality, reliable equipment, positive customer feedback is crucial. "Our client has seen cost savings both on time and manual maintenance," says Koutoufides. "That's the kind of outcome we strive to achieve." *MultiCyclone is designed to filter sediment that is heavier than water; floating debris cannot be filtered out by centrifugal filtration.

|

02 9898 8686 36 South Street, Rydalmere, NSW, 2116

|

Water Pressure Pump for Homes by Waterco

Water Pressure Pump for Homes by Waterco Leaf Trapper for Swimming Pools by

Leaf Trapper for Swimming Pools by Variable Speed Pool Pump for

Variable Speed Pool Pump for Side Channel Blower for Spas by Waterco

Side Channel Blower for Spas by Waterco Enhancing Public Spaces with Form,

Enhancing Public Spaces with Form, Waterco Secures Coveted Spot in ASX All

Waterco Secures Coveted Spot in ASX All Waterco's Glass Pearl Filter Media Sets

Waterco's Glass Pearl Filter Media Sets 10-Year Warranty on Cartridge Filters

10-Year Warranty on Cartridge Filters Underwater Halogen Lights for Pools by

Underwater Halogen Lights for Pools by Elevating Pool Builds with Waterco's

Elevating Pool Builds with Waterco's Premium Water Filtration for the

Premium Water Filtration for the Waterco Releases Next-Gen Cordless Pool

Waterco Releases Next-Gen Cordless Pool Spa and Wellness Industry Relies on

Spa and Wellness Industry Relies on Pool and Spa Controller and Automation

Pool and Spa Controller and Automation Waterco Announces New Electroheat ECO-VS

Waterco Announces New Electroheat ECO-VS Waterco Announces First Commercial

Waterco Announces First Commercial Waterco Dominates Pool and Spa Industry

Waterco Dominates Pool and Spa Industry Waterco Pumps Ensures Clean Water for

Waterco Pumps Ensures Clean Water for Hybrid Sanitisation System by Waterco

Hybrid Sanitisation System by Waterco Waterco 10-year Warranty 2024

Waterco 10-year Warranty 2024