Movement Joint Systems from Unison Joints

Polished concrete, bulky-goods EJ system: Projects by Unison Joints

Movement joints are constructed to provide relief from ductile stress that is caused by changes in ambient temperature. Concrete shrinks and expands along with changes in moisture, temperature, and seismic movement. If necessary measures aren't taken to address the contraction and expansion of concrete, unsightly irregular cracks will appear.

Expansion or movement joints are designed to segment slabs, walls and columns in structures to enable thermal, shrinkage, seismic, wind and other movement to occur. Structural movement gaps are created in concrete slabs, columns and walls by forming, tooling, sawing, and placing of joint formers.

Vertical and horizontal movements between adjoining parts of the structure are accommodated by movement joint systems. This mechanism minimises the appearance of cracks on the surface of a concrete. The movement joint system must be carefully designed, located, and installed properly.

The movement joints from Unison Joints are designed according to their six-way movement principle, which permits a multi-directional, six-way movement pattern that minimises the risk of damage to the surrounding substrate, prevents deformation of cover plates, and shearing of screws that holds the expansion joint system firmly in its place.

Unison Joints broad range of expansion joint systems and cover plates are widely used in hospitals, multi-storey car parks, grandstands, sports stadiums, airports, transit terminals, bridges, wharves, shopping centres, supermarkets, department stores, warehouses, and loading facilities - across Australia, the Middle East, New Zealand and Asia.

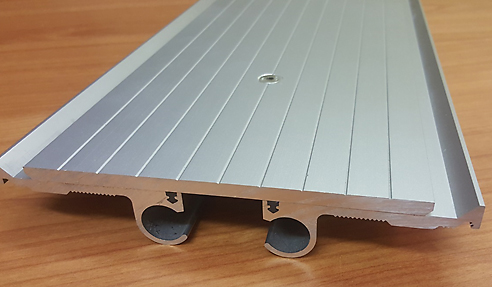

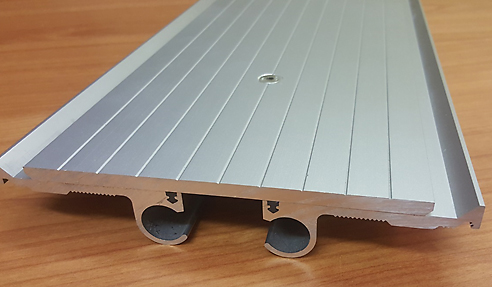

Recently, Unison Joints completed a retrofit project for Masters Northmead using the Designer Range movement joints system. Dz150H (Designer Range) joints have a revolutionary streamlined minimalist design, where a combination of a slim visual width, low profile, anchored with hidden fixings. Dz150H is compatible with tiles, vinyl, carpet, epoxy, and exposed concrete finishes. Its low profile and slender width allow for minimal substrate rebating. Unlike other movement joints system, Dz150H don't leave an unattractive grout line. Its hidden fixing edge-line is ideal for use in polished concrete.

Dz150H (Designer Range Dz H) is designed to accommodate heavy-duty traffic and pedestrian load application like in Masters Home Improvement in Northmead. Dz150H uses structural grade 6061 T6 alloy coverplates which meets the high demanding, bulky-goods retail environment where shoppers, private vehicles, industrial forklifts, pallets trolleys, and delivery trucks are constantly in use. Its optional bead-blasted cover plate has a certified P5 or V Rating (R11) under Slip Resistance Testing (AS 4586 2013) for maximum safety of pedestrians.

The Dz150H design also employs the use of composite cbars. This means that the system is corrosion-free, and versatile to use where pooling water may be encountered.

Unison Joints works hard to continuously improve their customised solutions and line of expansion joint systems.

Book a consultation with Unison Joints for more information on Dz150H (Designer Range) movement joints today.

Please be advised that Unison Joints is unaffected by COVID-19 as our manufacturing products are not sourced from China.

|

Expansion Joint Cover for Aluminium

Expansion Joint Cover for Aluminium Low-Profile Floor Expansion Joint Cover

Low-Profile Floor Expansion Joint Cover Flexible Waterproof Expansion Joint

Flexible Waterproof Expansion Joint Watertight Expansion Joint Gap Seal for

Watertight Expansion Joint Gap Seal for 100% Australian-Owned Materials for

100% Australian-Owned Materials for Unison Redefining Quality for Over 24

Unison Redefining Quality for Over 24 How to Select the Right Expansion Joint

How to Select the Right Expansion Joint Seismic and Fire-Rated Joint Systems for

Seismic and Fire-Rated Joint Systems for The New Sydney Fish Market Expansion

The New Sydney Fish Market Expansion Unison Joints at Oran Park Podium

Unison Joints at Oran Park Podium Fire-Rated Expansion Joint Systems for

Fire-Rated Expansion Joint Systems for Expansion Joint Cover for Concrete

Expansion Joint Cover for Concrete Carpark Expansion Joint Seal for

Carpark Expansion Joint Seal for EPDM Compression Seal for Carparks by

EPDM Compression Seal for Carparks by Cover Plate for Expansion Joints by

Cover Plate for Expansion Joints by Aluminium Floor Expansion Joint Covers

Aluminium Floor Expansion Joint Covers St Vincent's Hospital Upgrade Seismic

St Vincent's Hospital Upgrade Seismic Epoxy Grout for Nosing & Bedding of

Epoxy Grout for Nosing & Bedding of Slim Floor Coverplate with Hidden

Slim Floor Coverplate with Hidden Watertight Expansion Joint Solution from

Watertight Expansion Joint Solution from