"Hydrogen peroxide, which is hydrogen and oxygen, does not form any by-products when you're adding other chemicals."

The Cameron Highlands is situated in Pahang, West Malaysia, approximately 85kms from Ipoh and about 200kms from Kuala Lumpur. At an elevation ranging between 1135 metres to 1829 metres above sea level, it is the country's highest point accessible by road.

Considered the epicentre for Malaysia's vegetable and flower farming sectors, the region is famed for its lush, fertile soil, cool climate, steeply farmed hillsides, tea plantations, and sprawling strawberry farms.

In the midst of this is Cameron Highlands' hydroponic lettuce farm, which has become a popular tourist attraction since opening in 1990.

Challenges

Hydroponics is a branch of agriculture where crops are grown in water instead of soil. Depending on which of the six types of hydroponic systems are used - Drip, Ebb and Flow, NFT (nutrient film technique), Wick, Water Culture and Aeroponic - the plant's roots are either suspended in, flooded with or misted using a nutrient-rich solution that enables the plant to grow.

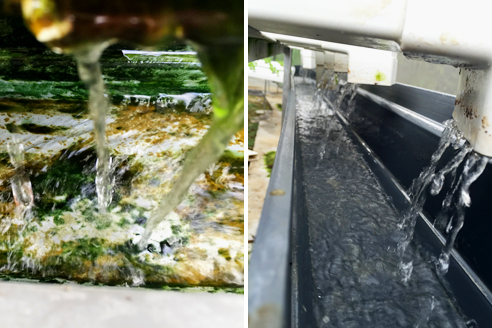

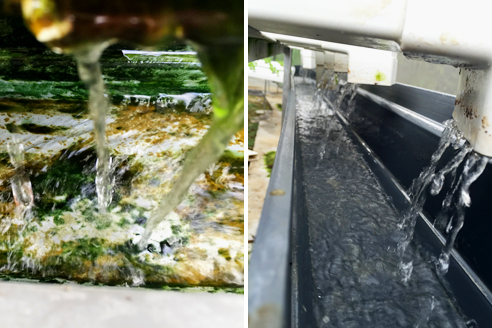

"The challenge with this massive farm involved the open water races and drains, which is essentially a network of long channels where each lettuce is individually grown and fed," explains Hydroxypure inventor Nick Briscoe. "The channels were filling up with algae and, when lettuce gets bacteria in it during the propagation phase, it dies very quickly once it's picked."

A further challenge involved the lack of quality starting water in Malaysia. Domestic sewage, livestock farming and other liquid organic waste products are said to be responsible for a large number of polluted waterways throughout the country.

Surmises Nick: "So we had three challenges to address - one was cleaning up the water races as they were getting clogged up with algae, two was creating a healthier lettuce that would last longer after it was picked, and three was improving propagation time."

Algae growth completely eliminated from growing channels.

Objectives

Two trials using Waterco's Hydroxypure filtration system were set up using food grade H2O2 at 35 per cent: Trial 1 was small scale with 100 crops, while Trial 2 involved a larger scale involving 16,000 crops spread out over one acre.

With both trials, the objectives were as follows:

- To compare growth rate with control set;

- To compare disease/mortality rate with the control set; and

- To prevent algae from growing in the hydroponics channels and drains.

"The first thing that happened was that we fixed the problem in the water races, so they were all clean and free of algae," Nick explains. "The second significant thing that happened was that propagation went from 55 days down to 31 days."

Benefits

Hydroxypure's hybrid ozone technology stimulates the action of the sun by generating a high-intensity wavelength of light, which in turn produces a clean form of ozone that is free of impurities. The natural flocculating effect that ozone has on water greatly increases the capability of the filtration system to be able to filter out oxidised contaminants in the water, leaving hydroponic water clean and crystal clear.

"Hydrogen peroxide, which is hydrogen and oxygen, does not form any by-products when you're adding other chemicals," says Nick. "This enabled us to achieve positive results on the hydroponic farm without upsetting the other growing systems."

Water Pressure Pump for Homes by Waterco

Water Pressure Pump for Homes by Waterco Leaf Trapper for Swimming Pools by

Leaf Trapper for Swimming Pools by Variable Speed Pool Pump for

Variable Speed Pool Pump for Side Channel Blower for Spas by Waterco

Side Channel Blower for Spas by Waterco Enhancing Public Spaces with Form,

Enhancing Public Spaces with Form, Waterco Secures Coveted Spot in ASX All

Waterco Secures Coveted Spot in ASX All Waterco's Glass Pearl Filter Media Sets

Waterco's Glass Pearl Filter Media Sets 10-Year Warranty on Cartridge Filters

10-Year Warranty on Cartridge Filters Underwater Halogen Lights for Pools by

Underwater Halogen Lights for Pools by Elevating Pool Builds with Waterco's

Elevating Pool Builds with Waterco's Premium Water Filtration for the

Premium Water Filtration for the Waterco Releases Next-Gen Cordless Pool

Waterco Releases Next-Gen Cordless Pool Spa and Wellness Industry Relies on

Spa and Wellness Industry Relies on Pool and Spa Controller and Automation

Pool and Spa Controller and Automation Waterco Announces New Electroheat ECO-VS

Waterco Announces New Electroheat ECO-VS Waterco Announces First Commercial

Waterco Announces First Commercial Waterco Dominates Pool and Spa Industry

Waterco Dominates Pool and Spa Industry Waterco Pumps Ensures Clean Water for

Waterco Pumps Ensures Clean Water for Hybrid Sanitisation System by Waterco

Hybrid Sanitisation System by Waterco Waterco 10-year Warranty 2024

Waterco 10-year Warranty 2024