The refurbishment of a failed flat roof is the most common waterproofing

problem that the building industry is coming across. Taking all the

variables into consideration when specifying a waterproofing solution is

not an easy process.

Here are a few steps to consider when undertaking a roof refurbishment

project:

In addition the financial burden associated with the roofing works

necessary to reinstate the integrity of the roof waterproofing can be

significant.

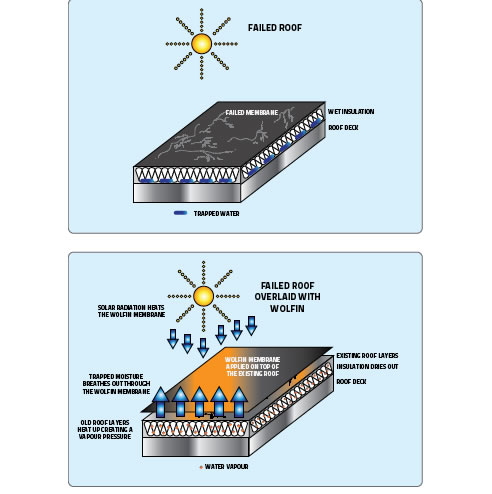

Diagnosis of the problem may not be straightforward. Water could be

collecting within the roofing layers due to several reasons.

STEP 2 Environmental Responsibility

When undertaking a roof

refurbishment project, the

use of WOLFIN products

can lower your costs

because you save the

expensive component of

stripping up & disposing of

the old failed membrane.

By avoiding construction

waste, you can also

actively help to preserve

the Environment.

One of Wolfin's many unique characteristics:

Unrivalled Bitumen

Resistance

The refurbishment of old

existing bitumen based &

liquid applied membranes

represent the majority of all

roofing rectifications.

Step 3 Select your Waterproofing Solution Wisely

Refurbishment with Wolfin roofing & waterproofing membranes has been

a tried & trusted solution for more than 50 Years on all continents of the

globe, covering millions of square metres of flat roofs, green roofs &

building surfaces.

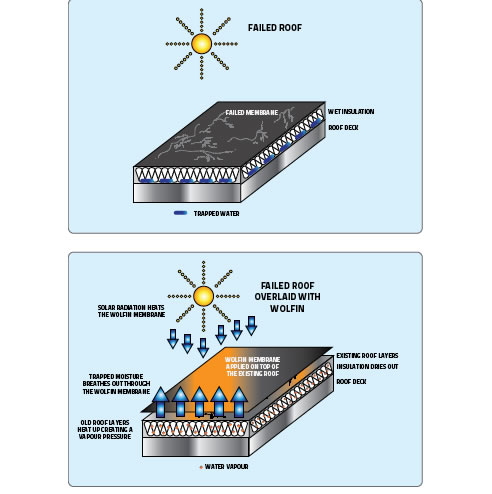

In most cases the old membrane is retained & the new Wolfin Membrane is

installed directly over the existing failed membrane (including bitumen)

Of all the Thermoplastic roofing & waterproofing membranes in the

market, WOLFIN offers the highest water vapour diffusion permeability,

which allows the trapped moisture in the roof layers to completely dry out.

Benefits of a Wolfin Installation/Refurbishment

- Warranty issued by the supplier (Labour & Materials)

- Saves you money

- Reduces the programs duration

- Service Temperature Range -25C - +85C

- No open flame

- Reduces the environmental impact (no disposal of the old failed

roofing membrane components)

- On-site Technical assistance

- Manufactured & Engineered in Germany

- Can be left exposed- UV Stabe

- Highly Flexible

- Bitumen Compatible

With over 50 years of experience in the single ply membrane market,

WOLFIN set out to develop a roof refurbishment solution that minimised

the cost to the client, that guaranteed the prolonged performance of the

existing roofing materials and which reduced disruption to the building

occupier.

WOLFIN based their solution around the ability to keep the majority of

existing roofing materials, which formed part of the failed roof

construction in place, whilst providing a new overlay membrane, which

dried out the moisture within the failed roofing layers.

Of all the waterproofing membranes available in

the market the WOLFIN membrane offers the

lowest vapour resistance and as a consequence

achieves the highest vapour permeability.

Steel Sleeves for Bund Walls by Projex

Steel Sleeves for Bund Walls by Projex Mechanical Sealing Solutions for Pipe

Mechanical Sealing Solutions for Pipe Protection Mat for Infrastructure

Protection Mat for Infrastructure Pipe Penetration Sleeves for Concrete

Pipe Penetration Sleeves for Concrete Polyester and PVC Waterproofing Membrane

Polyester and PVC Waterproofing Membrane Sound Deadening Mat by Projex Group

Sound Deadening Mat by Projex Group Benefits of Cosmofin Waterproofing for

Benefits of Cosmofin Waterproofing for How to Create Round Pipe Penetrations

How to Create Round Pipe Penetrations Advantages of Damtec Sub Ballast Mat by

Advantages of Damtec Sub Ballast Mat by Waterproofing Membrane for Fountains by

Waterproofing Membrane for Fountains by Century-Line Pipe Penetration Sleeves by

Century-Line Pipe Penetration Sleeves by Cosmofin PVC Waterproofing Membrane by

Cosmofin PVC Waterproofing Membrane by Why Balconies Leak by Projex Group

Why Balconies Leak by Projex Group Shockmat Protection Matting by Projex

Shockmat Protection Matting by Projex Advantages of the Link Seal System by

Advantages of the Link Seal System by UV Stable Waterproofing Membrane by

UV Stable Waterproofing Membrane by Steel Sleeves for Bund Walls by Projex

Steel Sleeves for Bund Walls by Projex Sub-Ballast Mats for Railway Projects by

Sub-Ballast Mats for Railway Projects by Environmentally Friendly Waterproofing

Environmentally Friendly Waterproofing Wolfin Membrane Planter Box

Wolfin Membrane Planter Box