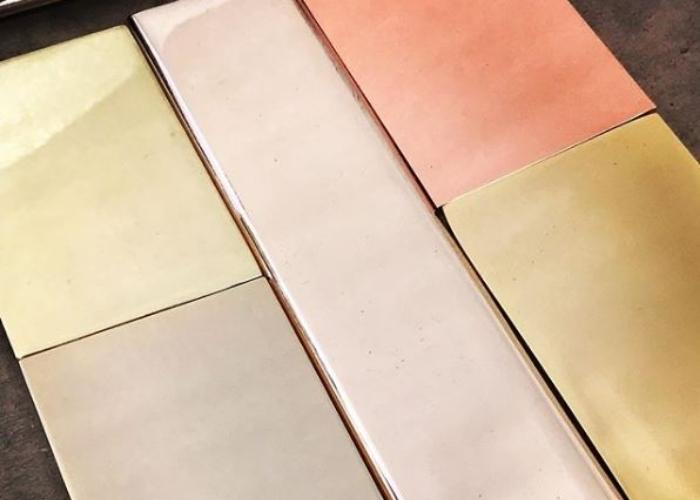

Brass vs Bronze vs Copper by Astor Metal Finishes Brass vs Bronze vs Copper by Astor Metal Finishes BRASS BRONZE COPPERMetal finishes are becoming more convoluted with imported metals and products and coloured stainless in the market. The most common questions and misunderstandings we see at Astor relate to brass & bronze. Here is a look at the real metals and what to expect and specify. In short, we advise specifiers to seek the metal finish (aesthetic and behaviour) they are after then seek advice from us or others based on the intended application & detail to decide on the best base metal to use to achieve longevity and corrosion resistance.

Definition of each metal

Properties & how to tell brass apart from bronze

Over time unlacquered brass, bronze, and copper will patina, tarnish, darken, dullen, and eventually verdigris if in contact with salt for an extended period of time. Unlacquered copper is the most reactive to the environment and will verdigris faster than brass or bronze when in contact with salt. Availability of BRONZEBronze proper is not only a rare & expensive metal alloy but also limited to mostly castings and engineering plates. For decorative architectural use, bronze profiles are rarely seen however we do see smaller production runs of bronze custom castings. The majority of bronze we see at Astor are these custom castings for decorative elements and trophies, some classic car parts and older marine hardware. Bronze is available in a multitude of alloys- meaning different colours and properties. Availability of BRASSBrass is much more readily available in stock and profiles than bronze. Brass is available in imperial dimensions. Brass metal is the answer for trafficable surfaces, work surfaces, and stair treads for example. The most common issues with brass metal are the variety of alloys (resulting in different colours between sheet and flat bar for example) and the joining of brass to ensure the same colour and properties results. Availability of COPPERCopper is limited to panels, rods, flat bars, and tubes. Profiles such as channel and angle would be considered custom extrusions and both timely and costly to source.Availability of Stainless and AluminiumThis is where electroplating can be your project's success. A huge array of extrusion and profiles are readily available in both aluminium and stainless. Stainless benefits include strength, and corrosion resistance, and can also be pre-polished while aluminium is light, cheaper, and able to be extruded into so many custom profiles. Both can be welded before electroplating for 2D and 3D frames. Many projects will have brass, aluminium, stainless, and mild steel in the same space which can all be finished with electroplating to achieve the same finish and aesthetics. Astor "Brown Bronze" range is AGED BRASS.

CASE STUDIES1. ARIA TREEHOUSE APARTMENTS, West End Brisbane, ARCTURUS NATURAL Medium Brown Bronze (unlacquered)

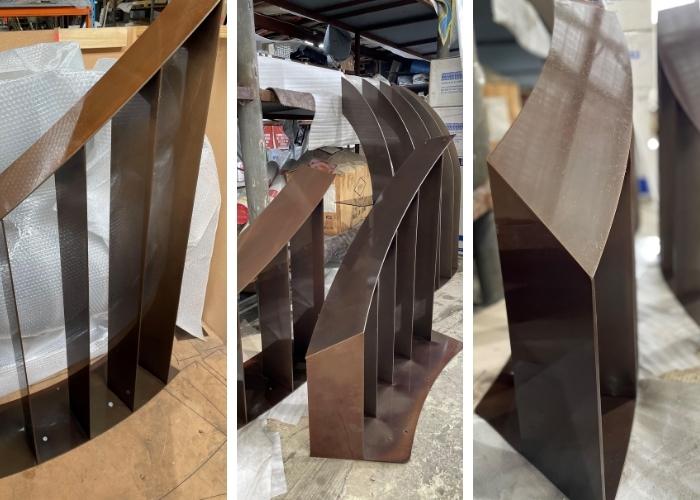

2. OPERA RESIDENCES, Circular Quay Sydney Stainless tree grates and furniture- all brass plated and aged, Dark aged brass CENTAURI NATURAL 3. ACT METRO, Bike racks- made in stainless. Finished in Dark aged brass CENTAURI NATURAL 4. The Sea Deck- https://astormetalfinishes.com/projects/seadeck/ Stainless for its strength, availability and ability to weld mesh and tube before brass-plating with light patina- TUCANA NATURAL Why they wanted brass/bronzeSeaDeck is not an ordinary boat in Sydney harbour. The standard stainless we commonly see on commercial vessels was never going to be good enough for this beautiful vessel built on the Nile. From the designers AZBCreative:"Sydney now has a venue worthy of our jaw-dropping harbour. We designed a grand cruiser with bespoke fittings and finishes and a twist on classic nautical design, bringing the style and elegance of the Riviera to Sydney. Curated decorations and iconic palm trees add to the vintage Lido vibe. The challenge was to create a lush, VIP experience while designing for the harsh elements- an interior which would be exposed to wind, rain, and sun." Why it was proving to be problematic brass/bronzeThe brief required big, strong structural frames for the bespoke bar work. Brass was too soft and the joining of brass is often problematic, during fabrication and also over time braised joins will patina at a different rate and shade to the brass tube, and further weaken over time. For the required spans, a brass tube would have required a thicker tube which was more expensive and heavier. Brass fabricators are far fewer than stainless fabricators which is resulting in limited and expensive fabricators. Bending of the brass hollow tube results in further weakening of the already weak metal. How Astor resolvedAstor encouraged the use of stainless steel, with a heavy brass plating. This allowed the readily available stainless steel profiles to be used including mesh, square tube, rod and fixings. The strength of the stainless permitted a lighter gauge, lighter and more economical than brass. TIG welds resulted in stronger joins that do not deteriorate over time and the brass plating, of course, covers the profile, fixings, and welds. The result is a strong and durable bespoke large frame system that behaves and looks as intended finished within 3 weeks and lasting for years. Visit www.astormetalfinishes.com for more information on brass vs bronze vs copper as well as other metal finishes.

|

02 9727 5622 93 Malta Street, Fairfield East, NSW, 2165

|

Dark Bronze Finishes for Lounges and

Dark Bronze Finishes for Lounges and Brass Plating for Handrails by Astor

Brass Plating for Handrails by Astor Tips for Choosing Base Metals by Astor

Tips for Choosing Base Metals by Astor Metal Finish Matching Services by Astor

Metal Finish Matching Services by Astor Benefits of Electroplating Metal by

Benefits of Electroplating Metal by Care for Chrome Finishes by Astor Metal

Care for Chrome Finishes by Astor Metal Electroplated Oiled Light Bronze Finish

Electroplated Oiled Light Bronze Finish Advantages of Silver Plating Metal by

Advantages of Silver Plating Metal by Specifying the Correct Finish for Metals

Specifying the Correct Finish for Metals Lacquer on Metal Finishes by Astor Metal

Lacquer on Metal Finishes by Astor Metal Advantages of Metal Finishing by Astor

Advantages of Metal Finishing by Astor Electroplated Rangehood for Kitchens by

Electroplated Rangehood for Kitchens by Copper Plating for Kettles by Astor

Copper Plating for Kettles by Astor How to Choose the Best Metal Substrate

How to Choose the Best Metal Substrate Metal Finish Matching by Astor Metal

Metal Finish Matching by Astor Metal Electroplated Metal Furniture by Astor

Electroplated Metal Furniture by Astor Electroplated Finishes at Prohibition

Electroplated Finishes at Prohibition Polished Gold with Clear Gloss Finish by

Polished Gold with Clear Gloss Finish by Perforated Panel Desk Screen by Astor

Perforated Panel Desk Screen by Astor What Base Metals to Use with Astor Metal

What Base Metals to Use with Astor Metal