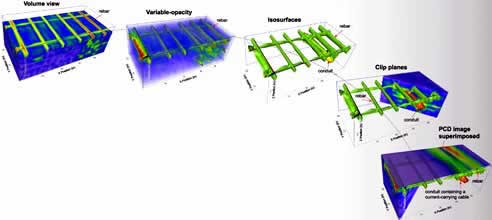

Why concrete x-ray is necessary by ScanMan The engineers and people in the construction industry constantly necessitate reliable and non-destructive measures to locate targets in the concrete structures before drilling or cutting. For this GPR or Ground Penetrating Radar is used. It is easy to use and has proven its field durability. It gives accurate results. Concrete x-ray can be used for various purposes. Conducting a synchronized concrete inspection analysis by using radar to locate rebar, tension bars, plastic and optic conduits is possible by the use of concrete x-ray. Voids within the concrete slabs and beneath them can be also be detected by using this application. Concrete inspection survey of the concrete walls, concrete floors, concrete slabs, airport runways, tunnels and dams can also be conducted. At times concrete slab condition has to be determined. This can be done and its relative thickness, deterioration and other structural problems can be inspected. The result is instant and the data can be pulled up on the computer. By seeing the images on the computer, realistic data can be interpreted immediately. The real theory behind GPR is that radar pulses are generated on a surface antenna. These are transmitted into the ground. When these pulses encounter buried discontinuities like stones, conduits etc some of them are reflected back towards the surface whereby they get recorded at the antenna. When the speed of the pulses traveling is calculated as against the time, measurement of the depth of the discontinuities can be taken. This makes GPR a geo-physical tool. To record the GPR reflections the antenna is allowed to move along the surface of ground within a certain pre-determined grid. Numerous reflections are registered per second. They are then plotted in a graphical manner. Collection of many transmissions in a grid produces 3D data. GPR can be effectively used before any excavation process. The GPR data is typically made of reflection profiles that contain noise and unnecessary reflections. These are produced by antenna radar, differences in coupling of energy with the ground, and numerous reflections that happen between the antenna and ground surface. During the entire process background noise is also produced. It is essential to remove the background noise so as to eliminate the horizontal lines that can occur in the profiles. Similarly the horizontal lines need to be eliminated from the reflection profiles. The elimination process is based on simple arithmetic calculation. After the removal of unwanted noise, the reflection profile becomes ready for image production.

|

0420 307 226 249 Towen Mountain Road, Towen Mountain, QLD, 4560

|

Nationwide Ground Penetrating Radar

Nationwide Ground Penetrating Radar Structural Scanning & X-ray Services by

Structural Scanning & X-ray Services by Concrete Scanning Brisbane - X-Ray

Concrete Scanning Brisbane - X-Ray Surface Penetrating Radar Equipment

Surface Penetrating Radar Equipment Detecting Leaking Pipes Brisbane |

Detecting Leaking Pipes Brisbane | Underground Scanning Services Brisbane |

Underground Scanning Services Brisbane | Surface Penetrating Radar Brisbane |

Surface Penetrating Radar Brisbane | 3D Underground Scanning Services

3D Underground Scanning Services Bore Hole Safety Check | Scan Man

Bore Hole Safety Check | Scan Man Underground Cable Location | ScanMan

Underground Cable Location | ScanMan Concrete Scan/Xray Queensland from

Concrete Scan/Xray Queensland from Geophysical Surveys with Concrete

Geophysical Surveys with Concrete Underground Cable Locating Equipment

Underground Cable Locating Equipment Ground Penetrating Radar Brisbane from

Ground Penetrating Radar Brisbane from Concrete X-Ray Brisbane from ScanMan

Concrete X-Ray Brisbane from ScanMan 3D Imaging Services Sunshine Coast from

3D Imaging Services Sunshine Coast from Utility Locators Sunshine Coast from

Utility Locators Sunshine Coast from Underground Locators Gold Coast from

Underground Locators Gold Coast from GPR Services Gold Coast from ScanMan

GPR Services Gold Coast from ScanMan Concrete Testing Services Gold Coast

Concrete Testing Services Gold Coast