The Eco Panel Autoclaved (AAC) Aerated Concrete wall panel, is a unique building material that contributes to a sustainable built environment. They provide an integrated solution to insulation needs and facilitate faster installation time.

AAC wall panels are manufactured using standard materials, including lime, sand, cement, and water mixed with a small amount of an expanding agent. The mixture is then poured into a mould where a chemical reaction takes place. The expanding agent in the mix creates small pockets of finely dispersed air bubbles.

The panels are cured under extreme heat and pressure to create a relatively stable and lightweight cellular structure - the unique physical properties of AAC wall panels. After the curation process, the mould is cut and sliced in the required sizes. Once they are cut, the wall panels undergo corrosion protection treatment to strengthen the panel's structural integrity.

The fortified aerated concrete wall panels are assembled into the final and most important part of the process: steam pressure, taking place inside a giant autoclave machine. This method gives Eco

Panel its moderate embodied energy content, superb thermal and acoustic insulation, and fire resistance property.

The benefits of Eco Panel AAC Wall Panels by CHAD

Environment Friendly

Autoclaved aerated concrete wall panels are fully biodegradable materials. They can be crushed into powder form and reused in road building projects, while the steel components can be melted to form new metal castings, thus, reducing environmental waste and landfill disposal.

Energy Saving

The unique combination of thermal resistance and thermal mass makes Eco Panel the material of choice for insulation projects. Its thermal efficiencies help reduce heating and cooling consumption, while still being able to provide a comfortable interior environment.

Fast Installation

The lightweight and highly integrated insulation material is easy to handle, transport and install, saving on valuable costs and construction time. Another factor that speeds up the installation process is the accurate measurement of Eco Panels. Autoclaved aerated concrete wall panels are always produced to required sizes and lengths as they leave the factory, resulting in less on-site trimming and waste build up.

Fire Resistant

Eco Panel is ideal to use in fire rated applications. It is inorganic, incombustible, and does not explode. It provides a Load Bearing FRL of 240/240/240.

Noise Control

The closed air pockets found in AAC wall panels provide excellent acoustic insulation and can be used as an effective sound barrier.

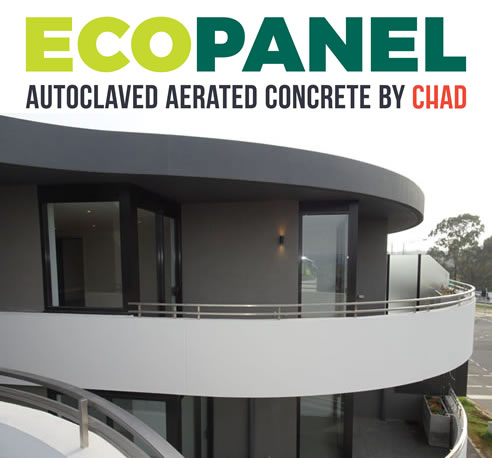

Eco Panel AAC wall panels provide a sustainable alternative to traditional masonry. Its excellent compressive strength and aesthetic appeal offer architects and designers the range and flexibility to comply with project specifications.

CHAD supplies and installs the versatile Eco Panel AAC wall panels in Victoria. They are ideal to use for reinforced wall and floor panels in residential, commercial and industrial applications.

Learn more about Eco Panel from our experts at CHAD by calling at 03 9544 8899 or visit their website at www.chadgroup.com.au today!

Bespoke Plaster Bulk Heads from CHAD

Bespoke Plaster Bulk Heads from CHAD Matrix Cladding Paint Application by

Matrix Cladding Paint Application by Sound Absorption Acoustic Panel

Sound Absorption Acoustic Panel Vitracore G2 Non-combustible Aluminium

Vitracore G2 Non-combustible Aluminium Non-combustible Composite Cladding from

Non-combustible Composite Cladding from Non-combustible Aluminium Cladding -

Non-combustible Aluminium Cladding - CodeMark Certified Thermal Facade

CodeMark Certified Thermal Facade Infill Clad & Rendered Facade in Red by

Infill Clad & Rendered Facade in Red by Luxury Residential Plaster Works

Luxury Residential Plaster Works Residential Interior & Exterior Plaster

Residential Interior & Exterior Plaster Curved Plaster Bulkheads for Homes &

Curved Plaster Bulkheads for Homes & ECO Wall Panels for Curved Apartment

ECO Wall Panels for Curved Apartment Exsulite® Thermal Facade System

Exsulite® Thermal Facade System Residential Wall Solutions Inside & Out

Residential Wall Solutions Inside & Out Commercial External Cladding & Rendering

Commercial External Cladding & Rendering Quietspace Acoustic Panels for Cafes

Quietspace Acoustic Panels for Cafes Decorative External Mouldings from CHAD

Decorative External Mouldings from CHAD Commercial Plasterboard from CHAD Group

Commercial Plasterboard from CHAD Group Autex Interior Acoustic Insulation from

Autex Interior Acoustic Insulation from Award Winning Walls and Ceilings from

Award Winning Walls and Ceilings from