Temporary Floor Protection that Breathes by SupaBord Why Surfaces Need to Breathe There are some instances throughout renovations when the incorrect floor protection products are used on the wrong surfaces. Despite these products serving the purpose as a temporary floor protection product, it can result in curing or newly finished surfaces to sweat between the surface and slab, causing an array of problems. Temporary floor protection comes in a wide variety of materials such as foam, paper, MDF, plastic, and corflute. It's important to know which floor protection product is suitable for the right material that is being laid on top of a surface. What causes surfaces to sweat? The thin layer of moisture appearing on the surface is due to condensation phenomenon. When the air with water vapours enters your house through windows, doors, or vents, and comes in contact with the cold tile floors, concrete slabs, or timber flooring. This meeting will change the state of water vapours to liquid. This event will usually occur due to the high content of water in the air filling the house, or lack of breathability when applying particular floor protection products on surfaces that require oxygen to prevent sweating. How will this affect my floors? If nothing is done about the built up condensation or moisture between the concrete and timber surface, the concrete slab becomes darker and results in efflorescence in the long run. This is a situation where the floor develops white patches caused when water that had previously been absorbed into the concrete floor slab comes to the surface and evaporates leaving behind mineral deposits carried from the concrete. Some of the signs that you may notice as a result of timber floors sweating include the following:

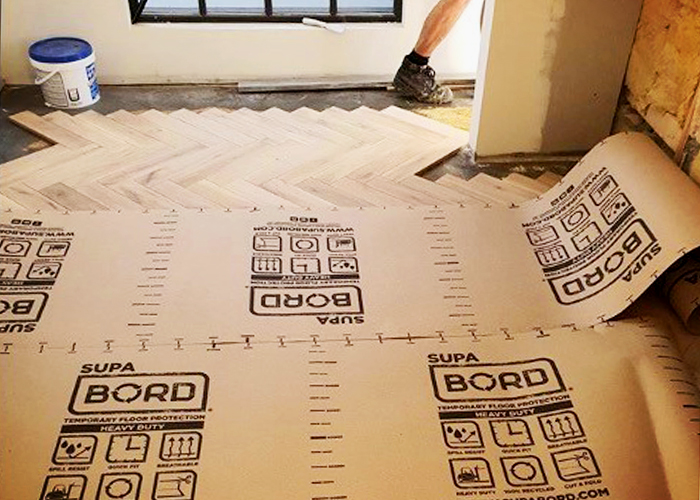

It usually takes surfaces 1-2 days to dry and around 28 days for a surface to cure. By not allowing the surface to breathe, sweating can often weaken the foundation of the slab concrete or flooring and create uneven surfaces. Before any further renovations take place, the SupaBord team strongly recommends that construction workers consider the type of flooring they're working on or over, ensuring the surface has the ability to breathe whilst curing or other renovation projects take place over timber or concrete surfaces. Both SupaBord Standard and Heavy Duty products are made out of a unique cardboard/paper material that is sourced from recycled materials that are breathable, reusable, and spill resistant.

|

(03) 9553 5362 32-34 Teton Court, Highett VIC 3190

|

Premium Floor Protection During

Premium Floor Protection During Custom Printed Flooring Protection

Custom Printed Flooring Protection