If there's one thing you never want to happen is a fire in a building you designed.

That's because, apart from the obvious risk to the occupants, it's likely a very public enquiry would pick over decisions you made.

Fingers get pointed, and reputations can be destroyed.

There is one main killer in a fire; smoke inhalation. It's well documented that most fire deaths around the world are caused by smoke inhalation and not burns.

Often in a fire situation smoke incapacitates people so quickly, they are overcome by it, and fail to make it to an accessible exit.

Smoke is lethal in two ways.

The first is smoke caused by toxic gases released by burning material.

And the second is reduced visibility from smoke.

These noxious fumes and a lack of visibility are a lethal combination attributable to the vast majority of fatalities in building fires not only in Australia, but also around the world.

This is one of the reasons Innovative Splashbacks® use the international award winning Plexiglas® acrylic.

Plexiglas® acrylic is renowned around the world as the "Non-smoker" because ...

... Plexiglas® acrylic produces NO toxic gas or smoke when burned.

Not all materials are the same.

There are several materials that are used to make splashbacks and wall panels.

And it's important to choose carefully and understand exactly what the material is made out of.

Plexiglas® acrylic burns almost without smoke, releases no acutely toxic gases and is quick and easy to extinguish. It has been tested to DIN 53436 for toxicity in plastics and passed with flying colours.

It is just one of the reasons it is used around the world in residential and commercial application since its invention in 1928 and is approved and used in aircraft windows and windscreens around the world to this day.

However, you must be careful about the material you use. Not all materials are the same. Some splashbacks are made from lower quality acrylics as well as other polymer materials such as PVC and vinyl.

And in a fire these materials may be a contributing factor to the deadly and toxic smoke produced.

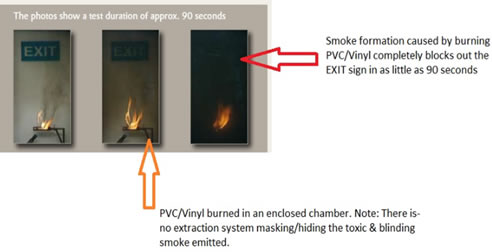

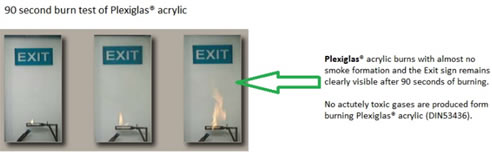

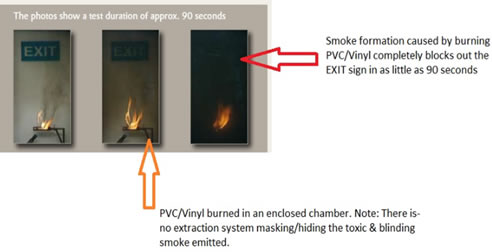

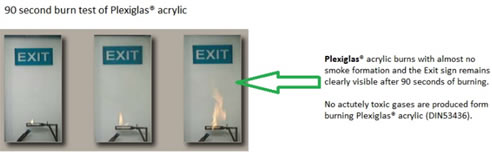

The following shows the result of a 90 second enclosed chamber burn test of Plexiglas® acrylic versus PVC/vinyl.

This test method is comparable to DIN4102 used to assess the smoke density of burning materials.

It demonstrates the amount of smoke produced when burning PVC/vinyl polymer material. And a second test showing effect of Plexiglas® acrylic burning.

Burn test of PVC/Vinyl

In as little as 90 seconds the chamber is full of thick black smoke completely blocking out visibility of the Exit sign. It is important to note both PVC and vinyl also produce deadly toxic gases when burned.

It's no surprise many countries are phasing out PVC including Sweden, Spain and Germany.

Plexiglas Burn Test

As you can see there is almost no smoke produced by burning Plexiglas® acrylic for 90 seconds. The Exit sign remains perfectly visible.

While there are many factors in any major fire, the safest option is ensuring all the materials you choose help reduce toxic emissions and smoke.

Click here to see where else around the world Plexiglas® acrylic has been used and why acrylic splashbacks have stood the test of time

Find out more about Innovative Splashbacks® by clicking here.

See the latest kitchen, bathroom, laundry and commercial projects here: http://www.facebook.com/InnovativeSplashbacks

Note: This article describes the non-toxic and non-smoker elements of the acrylic used by Innovative Splashbacks®.

Innovative Splashbacks® apply paint and printed materials to the Plexiglas® acrylic in order to create painted and printed splashbacks and wall panels.

Innovative Splashbacks® painted and digital print acrylic splashbacks are proudly Australian Made.

Innovative Splashbacks® painted and digital print acrylic splashbacks are proudly Australian Made.

© 2016 Innovative Splashbacks Pty Ltd. All rights reserved.

Innovative Splashbacks® painted and digital print acrylic splashbacks are proudly Australian Made.

Innovative Splashbacks® painted and digital print acrylic splashbacks are proudly Australian Made.

Cut-To-Size Digitally Printed and

Cut-To-Size Digitally Printed and Printed and Painted Acrylic Splashback

Printed and Painted Acrylic Splashback White and Colour Matched Commercial

White and Colour Matched Commercial Coloured and Printed Acrylic Splashbacks

Coloured and Printed Acrylic Splashbacks Acrylic Splashbacks for Commercial

Acrylic Splashbacks for Commercial Acrylic Splashbacks for Clinics, Schools

Acrylic Splashbacks for Clinics, Schools Printed Shower Splashbacks by Innovative

Printed Shower Splashbacks by Innovative Kitchen Splashback for Aged Care by

Kitchen Splashback for Aged Care by Do-it-yourself Kitchen Splashbacks |

Do-it-yourself Kitchen Splashbacks | Luxury Printed Acrylic Splashbacks by

Luxury Printed Acrylic Splashbacks by Kitchen Splashbacks in Grey by

Kitchen Splashbacks in Grey by Acrylic Splashbacks for Medical Centres

Acrylic Splashbacks for Medical Centres Printed Splashbacks for Country Kitchens

Printed Splashbacks for Country Kitchens Custom Colour Acrylic Splashbacks from

Custom Colour Acrylic Splashbacks from Nature Themed Printed Splashbacks by

Nature Themed Printed Splashbacks by Painted or Printed Laundry Splashbacks

Painted or Printed Laundry Splashbacks Beach-themed Shower Walls by Innovative

Beach-themed Shower Walls by Innovative Medical Centre Splashbacks from

Medical Centre Splashbacks from Custom Shower Feature Walls by

Custom Shower Feature Walls by Contrasting Kitchen Splashbacks from

Contrasting Kitchen Splashbacks from