Performer Stage R&D from Design Quintessence

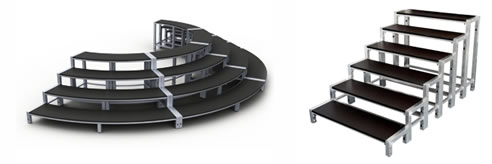

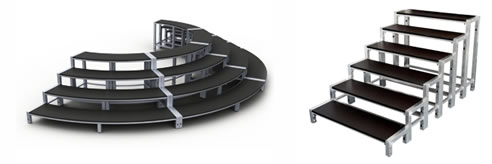

Performer Stage

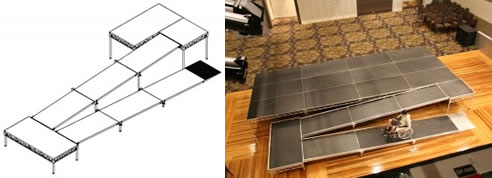

In 2007 Global Truss launched their Performer Stage which has the familiar truss style framing system. It is a simple staging system and simplicity often reflects good design. Design Quintessence worked with Global Truss to improve the design which saw the introduction of a leg clamping mechanism and full height extrusion for the plywood deck that protects the edge of the plywood.

Engineering & Testing

As with any staging equipment supplier in Australia, safety is the biggest priority. It goes without saying that any product Design Quintessence sells must be tested and certified. We engaged The University of Sydney to carry out testing of the Performer Stage using their advanced testing equipment and logging techniques. The tests exceeded the university engineers' expectation by a considerable margin (although DQ was not surprised by the results). These results were then used to assist in the issuing of the load certification from an independent engineer. Head to the link bellow for further images of the university tests.

R&D

Design Quintessence invests heavily in research and development. It is for that reason that they have always had in-house CAD design facilities and have expanded their team to include experienced industrial designers whilst using some of the best consulting engineers in Australia and Europe. They are always looking to improve their product design and develop new product ideas.

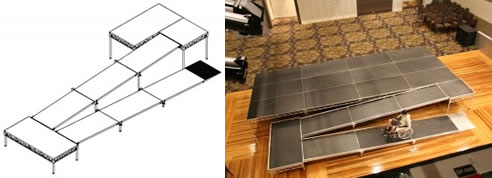

Disabled Access Ramp

An essential part of any staging system is a ramp option. Most stages have ramps but, as far as we are aware, no portable stage disabled access ramp actually meets the Australian Standards' requirement of a 1:14 design grade. DQ set about designing a disabled access ramp set at the 1:14 grade that was modular and light weight whilst maintaining the existing stage design aesthetic.

The result achieves exactly what was required. The 2.1m long decks are light weight and at the 1:14 grade, each reaches a vertical distance of 150mm. Therefore, the number of decks simply depends on the height of the stage, eg 900mm high stage = 6 decks (excluding the necessary landings). The leg mounting clamp assembly bolts to the side of the stage and these are what sets the correct gradient of the decks. Additionally, the decks and landings have special guard rails that bolt on to prevent wheels running over the edge of the ramp or landing.

Development of the ramp involved a R&D process of more than six months but the end result was worth the investment to produce what we believe is the only standard portable stage disabled access ramp that meets the Australian Standards that is available "off the shelf" in Australia.

Special Extrusion

Design Quintessence is often modifying product design for specific applications to tailor a solution for a client. One example is when they received a request from two clients for a recess in the Performer Stage top aluminium extrusion to accommodate a permanent Velcro loop strip to which skirting can be attached. This was a relatively straightforward design request but it meant DQ had to create a new die for the new extrusion especially for this project. Using their leading Solidworks software, they modelled the required extrusion and had a 3D prototype made before proceeding with the manufacture of the die and running the new extrusion. The turnaround was quite quick for the entire process and it ensured the functionality of the extrusion and, ultimately, that the final product was exactly as the client envisaged.

|

Portable Modular Space Partitions from

Portable Modular Space Partitions from Global Truss Solution for White Night

Global Truss Solution for White Night Cost Effective Temporary Project Site

Cost Effective Temporary Project Site Spec-Net Custom Portable Truss On Show

Spec-Net Custom Portable Truss On Show CareVision Featuring a Portable Truss

CareVision Featuring a Portable Truss Performer Stage Truss Stage System from

Performer Stage Truss Stage System from New 5 Chord Truss by Global Truss from

New 5 Chord Truss by Global Truss from Mechanical Protection of Cables | Design

Mechanical Protection of Cables | Design Car Ramp Staging Solutions | Design

Car Ramp Staging Solutions | Design Moulded Joining Plugs | Design

Moulded Joining Plugs | Design Disabled Access Stage Ramp | Design

Disabled Access Stage Ramp | Design Mic Kit - Foam Insert | Design

Mic Kit - Foam Insert | Design Chain Motor Road Case | Design

Chain Motor Road Case | Design Encore Mixer Road Case | Design

Encore Mixer Road Case | Design Radio Microphone Carry Case | Design

Radio Microphone Carry Case | Design Sound Equipment Lifters | Design

Sound Equipment Lifters | Design Safety Tape for Performance Stages |

Safety Tape for Performance Stages | Sentinel Cable Crossovers | Design

Sentinel Cable Crossovers | Design Global Truss Disabled Access Ramp |

Global Truss Disabled Access Ramp | Floor Tape Machine GaffGun Video |

Floor Tape Machine GaffGun Video |